In the pharmaceutical and nutraceutical industries, micro dosing requires extreme precision and control. Unlike standard capsule filling, micro dosing involves handling small quantities of potent or sensitive materials—often in milligram or even microgram amounts. To achieve accurate results, a reliable Capsule Filling Machine is essential.

This article explores how a high-precision Capsule Filling Machine supports micro dosing, what features to look for, and why an Automatic Filling Machine offers superior performance in this specialized application.

What is Micro Dosing?

Micro dosing involves the administration of very small, controlled amounts of active ingredients. In medicine, this is crucial for testing drug behavior in small trials or treating patients with ultra-low-dose therapies. In the supplement industry, micro dosing ensures the delivery of potent ingredients like melatonin, herbal extracts, or CBD in safe, low quantities.

To deliver such small amounts accurately, manufacturers must use a Capsule Filling Machine designed specifically for micro dosing tasks.

Why Micro Dosing Needs Precision

Standard capsule filling processes usually involve larger volumes, where minor variations may not significantly affect the final product. But in micro dosing, even a slight difference in fill weight can alter the dose effectiveness, safety, or stability. This is especially critical for clinical trials, pediatric medicines, or potent drugs.

That’s why companies must invest in an Automatic Filling Machine that delivers consistent and accurate dosing every time.

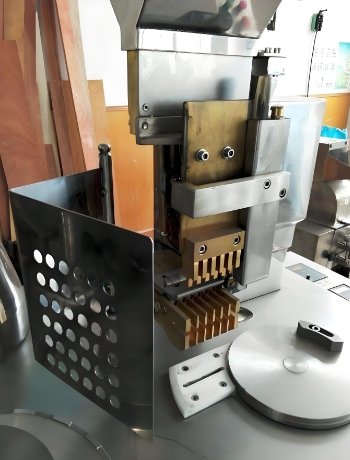

Features of a Micro Dosing Capsule Filling Machine

A Capsule Filling Machine made for micro dosing comes with advanced features that ensure ultra-precise filling. These features include:

1. High-Precision Dosing System

Machines use low-pressure tamping or micro auger systems to handle ultra-fine powders. This technology enables accurate filling even at 1 mg or below.

2. Enhanced Powder Flow Control

Micro powders can be light and sticky. Advanced powder flow systems prevent clogging and ensure even distribution.

3. Servo Motors and Automation

A modern Automatic Filling Machine includes servo motors for better speed and fill weight control. Automation also reduces human error.

4. Weighing Feedback System

Some machines have in-line weighing systems. These measure and adjust the fill weight in real-time to maintain accuracy.

5. Low Vibration Operation

For ultra-fine materials, vibration can cause separation or inconsistent filling. Micro dosing machines reduce vibration to preserve powder stability.

All these features work together to ensure the Capsule Filling Machine delivers the right amount in every capsule.

Advantages of Using an Automatic Filling Machine for Micro Dosing

Using an Automatic Filling Machine brings many advantages to micro dosing operations:

1. Superior Accuracy

Automation ensures consistent results for each capsule. No underfill or overfill problems.

2. Higher Throughput

While manual machines are slow and labor-intensive, automatic models can handle thousands of capsules per hour with exact dosing.

3. Less Waste

Fine powders are expensive. Precision filling reduces waste, saving money and preserving material.

4. Better Safety

For potent drugs, automated systems reduce operator exposure. Closed designs ensure safety for both operators and products.

5. Scalability

You can scale up production easily. Start with small batches for trials, then move to larger production with the same machine.

For businesses focused on quality, safety, and efficiency, the Automatic Filling Machine is the right choice.

Who Needs Micro Dosing Machines?

A Capsule Filling Machine for micro dosing is ideal for:

- Pharmaceutical R&D labs

- Clinical trial centers

- Pediatric drug manufacturers

- Veterinary medicine producers

- Nutraceutical companies

- Psychedelic therapy suppliers

- Specialty supplement brands

These industries depend on precision, consistency, and small-batch production. A dedicated Automatic Filling Machine supports all these goals.

Comparing Manual vs. Automatic Capsule Filling for Micro Dosing

| Feature | Manual Capsule Filling Machine | Automatic Filling Machine |

|---|---|---|

| Accuracy | Low | Very High |

| Speed | Slow | Fast |

| Labor Cost | High | Low |

| Dose Control | Poor | Excellent |

| Waste | High | Minimal |

| Ideal For | Hobby use | Professional production |

While manual capsule fillers are affordable, they are not reliable for micro dosing. An Automatic Filling Machine provides far better performance for professional use.

Common Capsule Sizes for Micro Dosing

For micro dosing, small capsule sizes are preferred. Sizes 4 and 5 are commonly used. However, the Capsule Filling Machine must be able to fill even these tiny capsules with accuracy.

Ensure your machine supports multiple capsule sizes and has quick changeover features. This allows flexibility and minimizes downtime between product runs.

Choosing the Right Micro Dosing Capsule Filling Machine

Before buying a Capsule Filling Machine, ask these questions:

- What is your desired fill range (mg or µg)?

- What type of powder will you use (sticky, fine, granular)?

- What capsule sizes do you need?

- Do you require a batch or continuous filling process?

- Will you need an inline weighing system?

A good supplier will help you choose the best Automatic Filling Machine based on your needs and product type.

Maintenance and Training

A high-precision Capsule Filling Machine requires regular maintenance to ensure performance. Clean all parts after each batch. Calibrate the system regularly to maintain dosing accuracy.

Also, train your staff to handle delicate powders and operate the Automatic Filling Machine safely. Training reduces errors and extends the life of your machine.

Cost Considerations

The cost of a micro dosing Capsule Filling Machine depends on:

- Degree of automation

- Fill range accuracy

- Capsule size support

- Speed and production capacity

- Added features like weighing or HEPA filters

Prices can range from $25,000 to $150,000. Though the investment is high, the machine quickly pays off by improving product quality and production efficiency.

Micro dosing requires precision. A standard capsule filler won’t do the job. You need a purpose-built Capsule Filling Machine with ultra-fine accuracy and gentle handling of powders. By investing in an Automatic Filling Machine, you gain control, speed, and safety in every dose.

Whether you’re producing pharmaceuticals or potent supplements, your success depends on reliable capsule filling. Choose a machine built for micro dosing, and stay ahead in a competitive industry.