For growing enterprises, the transition from hand pouring to using a dedicated filling machine for small business is the ultimate game changer. Whether you are bottling artisanal sauces, essential oils, or pharmaceutical supplements, the right equipment ensures that your “small” business can deliver “big” results with surgical precision. Our home page provides a full overview of how we support global manufacturing with these advanced technologies.

Why Automation is a Must for Modern Small Businesses

In 2026, manual filling is no longer just “slow”, it is a liability. According to industry data, manual filling leads to an average of 5-10% product giveaway due to overfilling. A professional automatic filling machine solution reduces this waste to less than 1%, instantly boosting your profit margins.

Core Benefits of Upgrading Today:

- Absolute Accuracy: Achieve $\pm 0.5\%$ dosing precision, ensuring every customer gets exactly what they paid for.

- Labor Efficiency: One semi automatic machine replaces three manual employees, allowing you to scale without increasing headcount.

- Hygienic Standards: High grade 304 or 316L stainless steel meets strict FDA and cGMP standards for retail and medical compliance.

- Professional Shelf Presence: Uniform fill levels across your product line build brand trust with retailers and consumers.

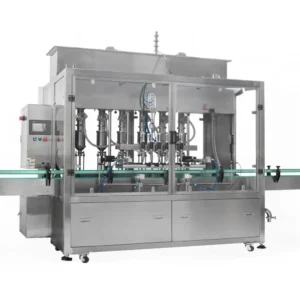

Liquid Filling Machine

Efficient equipment designed for accurate, spill free bottle packaging.

Powder Filling Machine

Automated equipment designed for fast, dust-free powder packaging.

Granule Filling Machine

High speed equipment for precisely measuring and bagging dry, free flowing grains.

Comparing Your Options: Semi-Automatic vs. Fully Automatic

Choosing the right level of automation depends on your current daily output and your 12-month growth plan. Many businesses start with a tabletop unit before upgrading to a comprehensive packaging machine solution.| Feature | Semi-Automatic Filler | Fully Automatic System |

| Production Scale | Boutique & Small Batch | Large-Scale Industrial |

| Output Velocity | 10 – 25 bottles per minute | 40 – 100+ bottles per minute |

| Nozzle Configuration | Single or Dual Nozzle | 4, 6, 8, or 12+ Nozzle Heads |

| Changeover Time | 5 – 10 Minutes (Manual) | < 5 Minutes (PLC Programmed) |

| Dosing Accuracy | $\pm 0.5\% – 1\%$ | $\pm 0.1\% – 0.5\%$ (Servo-driven) |

| Power & Utilities | 110V/220V + Small Compressor | 220V 3-Phase + Industrial Air |

| Cleaning Method | Manual Strip-Down | CIP (Clean-In-Place) Compatible |

Selecting the Right Technology for Your Product

Auger Fillers (For Powders)

- Servo-Driven Control: High-speed screw rotation delivers incredible weight accuracy for powders.

- Bridge Prevention: Integrated agitator blades stop powder from sticking in the hopper.

- Dust Containment: Closed-system design with extraction ports keeps your workspace clean.

- Interchangeable Tooling: Swap screw sizes to handle everything from 5g packs to 2kg bags.

Gravity Fillers (For Thin Liquids)

- Visual Symmetry: Uses the “Overflow” principle so every bottle looks perfectly identical.

- Rapid Sanitization: Simple fluid paths and fewer moving parts allow for faster cleaning.

- Drip-Free Performance: Equipped with mechanical seal nozzles to prevent waste.

- Low Maintenance Costs: Relies on natural physics, reducing the need for costly electrical pumps.

Piston Fillers (For High-Viscosity Creams & Pastes)

- Volumetric Precision: Fixed cylinder stroke ensures identical volumes regardless of density.

- Viscosity Mastery: Handles extreme thicknesses from salsas to adhesives without clogging.

- Minimal Product Shear: Gentle mechanical action protects the integrity of delicate mixtures.

- Anti-Drip Accuracy: Specialized nozzles provide a clean cut-off to eliminate “stringing”.

Frequently Asked Questions (FAQs)

1. How much space does a small business filling machine take up?

Most entry level machines are tabletop models that fit on a standard 4 foot workbench.2. Is it difficult to switch between different products?

Modern machines feature tool less disassembly for cleaning and changeovers in under 15 minutes.3. Does a filling machine require a special power outlet?

Most are designed for standard 110V or 220V single phase power.4. Can I use the same machine for liquids and thick creams?

If you choose a Piston Filler, yes. Piston technology is highly versatile and can handle thin liquids as well as thick pastes. However, a Gravity Filler is only suitable for thin, free-flowing liquids.

5. How do I clean the machine to avoid cross contamination?

Our machines are built with SOP (Standard Operating Procedure) cleaning in mind. Most contact parts are made of polished stainless steel and food-grade silicone, which can be flushed with hot water or sanitized with industry-standard cleaning agents.

6. Do I need an air compressor for a small filling machine?

Many semi-automatic and piston-driven machines are pneumatic, meaning they require a small air compressor to power the moving parts. If you don’t have an air supply, we also offer all-electric models.

7. What is the expected lifespan of these machines?

With basic maintenance (lubricating O-rings and cleaning after use), an industrial-grade filling machine for small business can easily last 10 to 15 years, even with daily use.