The beverage industry evolves quickly. Companies need advanced tools to stay competitive. A high-performing Beverage Filling Machine is key. Automation is also transforming how businesses operate.

This article highlights cutting-edge developments. These innovations improve efficiency, accuracy, and sustainability.

What Is a Beverage Filling Machine?

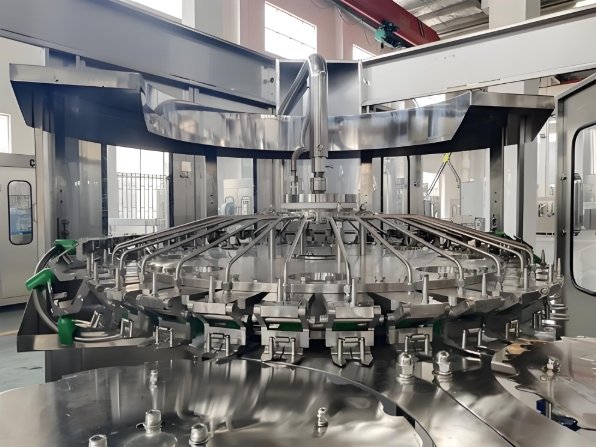

A Beverage Filling Machine fills liquids into containers. It works with bottles, cans, and cartons. Automation makes this process faster. Automatic Filling Machines now dominate the market.

Key Features

- Precise liquid measurement.

- Adjustable for different container sizes.

- High-speed performance.

Why Innovation Matters

Innovation drives industry success. It brings better technology. Faster, more accurate machines save time. They also reduce waste. Automatic Filling Machines use smart features. These include sensors and AI.

Top Innovations to Watch

1. Smart Filling Systems

Modern machines feature AI-powered controls. They adjust settings in real time. This reduces errors. Sensors ensure every container is filled accurately.

2. Energy-Efficient Designs

New models use less energy. They are eco-friendly. Manufacturers save on power costs.

3. Compact Machines

Space-saving designs are gaining popularity. Smaller factories benefit the most.

4. Multi-Function Machines

Many machines now combine tasks. They fill, cap, and label in one process. This improves efficiency.

5. Remote Monitoring

Operators can control machines remotely. Apps track performance and alert for maintenance.

Benefits of Modern Beverage Filling Machines

1. Increased Speed

Automation boosts production rates. Machines handle thousands of units per hour.

2. Enhanced Precision

Each container gets the exact liquid amount. This minimizes waste.

3. Improved Hygiene

Automation reduces human contact. It ensures cleaner operations.

4. Lower Costs

Energy-efficient machines reduce expenses. Automation cuts labor costs too.

Key Trends in Beverage Filling Machines

1. AI Integration

AI improves efficiency. It predicts maintenance needs. It also reduces downtime.

2. Sustainable Manufacturing

Eco-friendly materials and processes are trending. Companies focus on reducing their carbon footprint.

3. Versatility

Machines handle different liquids and container types. Flexibility is crucial for diverse product lines.

4. IoT Connectivity

Internet-connected machines are common. They offer better data analysis.

Applications of Beverage Filling Machines

Beverage Filling Machines are versatile. They work with many liquids. These include water, soda, juice, and milk.

Industry Uses

- Soft drink factories.

- Bottled water plants.

- Juice production lines.

- Dairy product manufacturers.

Challenges in Beverage Filling

Innovation helps overcome challenges. Traditional machines often lack precision. Manual operations are slow. Hygiene can also be a concern. Automatic Filling Machines solve these problems.

Common Issues

- Spillage during filling.

- High labor costs.

- Inconsistent liquid measurement.

Case Study: A Soft Drink Manufacturer

A company upgraded to an Automatic Filling Machine. Their output doubled. Spillage dropped by 50%. Energy use decreased significantly. The machine paid for itself in one year.

Maintenance Tips for New Machines

Modern machines require proper care.

Tips

- Clean nozzles regularly.

- Inspect sensors for accuracy.

- Lubricate moving parts.

- Follow the manufacturer’s guide.

Choosing the Right Machine

Investing in the right machine is vital.

Steps to Consider

- Assess your production needs.

- Choose a model with advanced features.

- Ensure it handles your beverage type.

- Look for energy-efficient options.

The right Beverage Filling Machine ensures long-term success.

The Future of Beverage Filling

The future looks exciting. Technology will continue to evolve. Machines will become faster and smarter. They will also be more eco-friendly.

Future Trends

- More AI integration.

- Fully automated systems.

- Better energy-saving features.

Innovation is reshaping Beverage Filling Machines. Advanced features improve efficiency and accuracy. Automatic Filling Machines lead the way. They offer speed, precision, and sustainability.

Investing in the latest technology ensures success. Stay ahead by embracing these innovations. The future of beverage filling is here.