Improving production speed is crucial for businesses handling powdered products. A Powder Filling Machine plays a vital role in streamlining operations. When optimized, these machines can significantly boost efficiency. This article explores practical ways to improve production speed using filling machines, focusing on Automatic Filling Machines.

Benefits of Optimized Production Speed

Efficient production speed brings multiple advantages:

- Higher Output: Meet growing demands easily.

- Reduced Costs: Lower labor and time expenses.

- Improved Accuracy: Ensure consistent filling.

- Enhanced Workflow: Minimize delays and errors.

Investing in the right machine and techniques can transform your operations.

Why Choose Automatic Filling Machines?

An Automatic Filling Machine enhances speed with minimal manual intervention.

Key Features of Automatic Filling Machines:

- Precision: Accurately measures powder amounts.

- Automation: Speeds up repetitive tasks.

- Versatility: Handles various container sizes.

- Reliability: Operates continuously without fatigue.

These features make them ideal for high-volume production.

Factors Affecting Production Speed

Several elements influence how fast your Powder Filling Machine performs.

1. Type of Powder

- Free-flowing powders are faster to fill.

- Sticky or clumpy powders require more time.

2. Machine Type

- Semi-automatic machines are slower than fully automatic ones.

- Automatic Filling Machines handle larger batches efficiently.

3. Container Size

- Smaller containers fill quicker.

- Larger or irregular shapes need extra time.

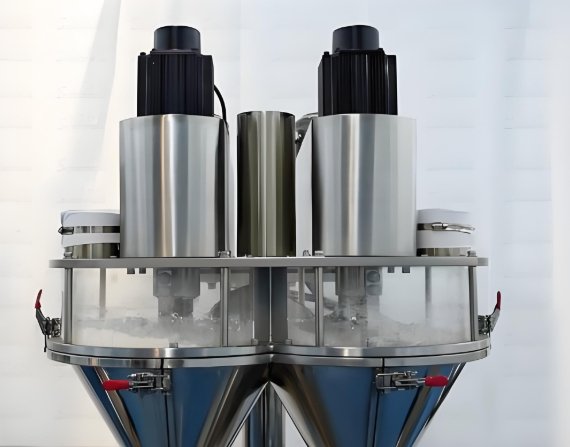

4. Hopper and Auger Design

- Proper design ensures consistent powder flow.

- Blockages slow down production.

5. Environmental Conditions

- Humidity can affect powder flowability.

- Stable conditions improve machine efficiency.

Tips to Improve Production Speed

Follow these strategies to enhance the speed of your Powder Filling Machine:

1. Upgrade to Automatic Machines

Switching to an Automatic Filling Machine is the easiest way to boost speed.

- Reduces manual effort.

- Ensures faster, consistent filling.

2. Optimize Machine Settings

Adjust machine settings to suit your production needs.

- Fine-tune speed controls.

- Match settings to powder type and container size.

3. Use High-Quality Components

Invest in durable hoppers, nozzles, and auger screws.

- Prevents frequent breakdowns.

- Maintains smooth operations.

4. Regular Maintenance

Clean and inspect the machine regularly.

- Avoids clogs and downtime.

- Keeps the machine running at optimal speed.

5. Minimize Manual Handling

Automate processes like container placement and removal.

- Speeds up workflows.

- Reduces human error.

6. Train Your Team

Train operators to handle the machine efficiently.

- Ensures proper usage of settings.

- Quickly resolves minor issues.

Advanced Solutions for Faster Production

Adopt advanced techniques to maximize efficiency:

1. Multi-Nozzle Filling Systems

Equip your Powder Filling Machine with multiple nozzles.

- Fills multiple containers simultaneously.

- Reduces overall cycle time.

2. Weighing and Filling Integration

Combine weighing and filling in one step.

- Increases speed without compromising accuracy.

- Ideal for high-precision needs.

3. Conveyor Automation

Add conveyors for automated container movement.

- Eliminates manual transfer delays.

- Ensures consistent throughput.

4. IoT-Enabled Machines

Invest in IoT-compatible machines for real-time monitoring.

- Detects issues immediately.

- Optimizes performance remotely.

Common Challenges and How to Overcome Them

1. Powder Spillage

Cause: Inaccurate settings or nozzle issues.

Solution: Adjust settings and inspect nozzles regularly.

2. Inconsistent Filling

Cause: Calibration errors.

Solution: Recalibrate the machine frequently.

3. Frequent Downtime

Cause: Poor maintenance.

Solution: Follow a strict maintenance schedule.

4. Clogs in the Hopper

Cause: Residual powder buildup.

Solution: Clean the hopper after each use.

The Role of Automation in Speed Improvement

Automation is the backbone of faster production.

Benefits of Automation:

- Consistency: Ensures uniform filling every time.

- Speed: Handles repetitive tasks quickly.

- Scalability: Easily meets higher demands.

An Automatic Filling Machine is essential for industries requiring speed and precision.

Improving production speed with a Powder Filling Machine involves the right mix of machine upgrades, maintenance, and operator training. Investing in an Automatic Filling Machine is a game-changer for boosting efficiency. Regular cleaning, calibration, and advanced techniques like multi-nozzle systems ensure optimal performance.

By following these tips, you can achieve faster production, reduce costs, and maintain high-quality standards.