Selecting the right Tube Filling and Sealing Machine is crucial. It ensures efficient and precise packaging. A reliable machine improves productivity. It reduces waste and downtime. Automatic Filling Machines also streamline processes. Choosing the right one requires careful consideration.

Understand Your Requirements

Before purchasing, evaluate your needs.

Key Questions to Ask:

- What type of products will you fill?

- Liquids, creams, or gels?

- What is your production volume?

- Low, medium, or high capacity?

- What tube materials will you use?

- Plastic, aluminum, or laminated?

These answers help narrow your choices.

Check the Filling and Sealing Accuracy

Precision matters in packaging. A good Tube Filling and Sealing Machine ensures consistent results.

Factors to Look For:

- Accurate Filling

- Measures exact quantities for each tube.

- Secure Sealing

- Ensures no leaks or contamination.

High accuracy maintains product quality.

Evaluate Speed and Capacity

Production speed is vital for efficiency. Choose a machine that matches your business scale.

Options to Consider:

- Low-Speed Machines

- Ideal for startups or small batches.

- High-Speed Machines

- Suited for large-scale manufacturing.

Ensure the machine can meet your future growth needs.

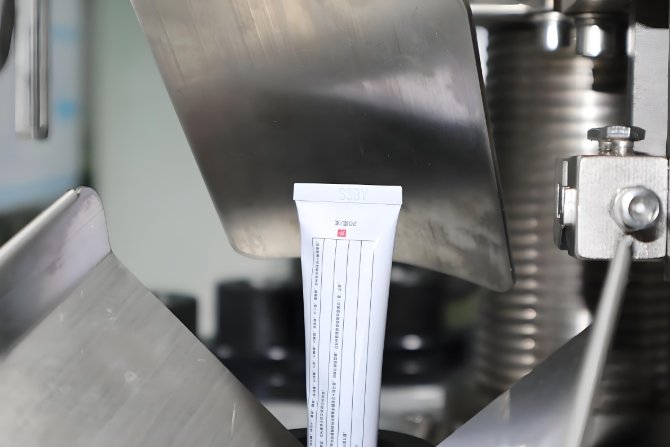

Prioritize Build Quality

A durable machine lasts longer. Inspect the build quality before purchasing.

Key Features to Check:

- Stainless Steel Construction

- Resists corrosion and ensures hygiene.

- Robust Components

- Handles wear and tear from daily use.

Durability reduces maintenance costs.

Focus on User-Friendly Features

Ease of use saves time. Choose a Tube Filling and Sealing Machine with intuitive controls.

User-Friendly Options:

- Touchscreen Interfaces

- Simplify machine operation.

- Automated Adjustments

- Adjust tube sizes or filling levels easily.

These features make operations smoother.

Assess Maintenance Requirements

Reliable machines are easy to maintain. Complex systems may cause delays.

Maintenance-Friendly Features:

- Self-Cleaning Mechanisms

- Reduce manual cleaning time.

- Modular Design

- Simplifies part replacements.

Less maintenance leads to more uptime.

Look for Safety Features

Safety is essential for operators and products. Ensure the machine includes safety features.

Common Safety Options:

- Emergency Stop Buttons

- Quickly halt operations if needed.

- Protective Shields

- Prevent accidents during use.

Safety features protect both workers and equipment.

Check Compatibility with Automatic Systems

Many businesses use Automatic Filling Machines. Ensure your Tube Filling and Sealing Machine integrates seamlessly.

Benefits of Compatibility:

- Streamlined Workflow

- Synchronizes with conveyors and cappers.

- Scalability

- Expands easily as production grows.

Automation improves efficiency.

Compare Costs and Value

Price matters but focus on value. The cheapest option may not be the best.

What to Consider:

- Initial Cost

- Does it fit your budget?

- Operating Costs

- Energy, maintenance, and parts.

- Return on Investment (ROI)

- Will it save time and money long-term?

Balance cost with performance.

Research the Manufacturer

A reputable manufacturer ensures quality. Investigate the company behind the machine.

Questions to Ask:

- How long have they been in business?

- Do they offer customer support?

- What do other buyers say about them?

Reliable manufacturers provide warranties and training.

Test the Machine Before Buying

Always test the machine if possible. Observe its performance under real conditions.

Key Things to Test:

- Filling Precision

- Check for consistency across samples.

- Sealing Strength

- Ensure the seal holds under pressure.

- Ease of Operation

- Evaluate how easy it is to operate.

Testing ensures you make the right choice.

Consider Customization Options

Some businesses need unique features. Customization ensures the machine meets specific needs.

Examples of Custom Features:

- Special Nozzles

- For thick or unique products.

- Additional Sensors

- For advanced quality checks.

Customization improves versatility.

Invest in Training and Support

Even the best machines need skilled operators. Choose a supplier offering training.

Support Options to Look For:

- Installation Assistance

- Helps set up the machine correctly.

- Technical Support

- Provides help during issues.

Good support ensures smooth operations.

A reliable Tube Filling and Sealing Machine enhances efficiency. Pairing it with an Automatic Filling Machine further boosts performance. Focus on your needs, machine quality, and features.

Research thoroughly before purchasing. Test the machine and assess the manufacturer. Look for value, not just price. A well-chosen machine improves production and saves costs.

Invest in quality for long-term success. With the right machine, your packaging process will thrive.