Every brand wants unique packaging. A Tube Filling and Sealing Machine helps achieve that. It ensures efficiency, precision, and consistency. Many industries rely on an Automatic Filling Machine to meet specific production demands.

Custom machines offer flexibility. They allow manufacturers to create unique designs and improve efficiency. This article explores the benefits, features, and factors to consider when choosing a custom Tube Filling and Sealing Machine.

1. Why Custom Tube Filling and Sealing Machines?

Not all products fit standard machines. Custom Tube Filling and Sealing Machines help brands stand out. They provide:

- Precision filling for unique product viscosities.

- Flexible sealing for various tube materials.

- Personalized design to meet branding needs.

- Increased efficiency for specialized production.

An Automatic Filling Machine ensures high-speed, accurate performance.

2. Key Features of a Custom Tube Filling and Sealing Machine

A custom Tube Filling and Sealing Machine must meet specific needs. Key features include:

A. Adjustable Filling System

It handles different viscosities, from thin gels to thick creams.

B. Versatile Sealing Options

Machines should support heat, ultrasonic, and laser sealing.

C. High-Speed Operation

An Automatic Filling Machine ensures fast, accurate production.

D. Multi-Tube Compatibility

Supports plastic, metal, and laminated tubes.

E. Easy Customization

Allows adjustments for tube sizes, designs, and materials.

F. Efficient Cleaning System

Quick cleaning reduces downtime and maintains hygiene.

3. Best Custom Tube Filling and Sealing Machines

Custom machines vary based on production needs. Below are the best options.

A. Fully Automatic Tube Filling and Sealing Machine

- Best for high-speed production.

- Ensures accuracy and efficiency.

- Ideal for large-scale operations.

B. Semi-Automatic Tube Filling and Sealing Machine

- Suitable for small to medium production.

- Requires minimal manual input.

- More affordable than fully automatic models.

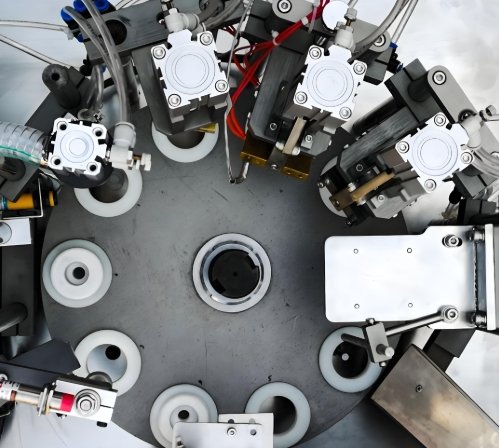

C. Rotary Tube Filling and Sealing Machine

- Uses a rotating system for efficiency.

- Handles different tube sizes.

- Ensures precise sealing.

4. Benefits of an Automatic Filling Machine

An Automatic Filling Machine improves production in many ways.

A. Speed and Precision

Fills and seals tubes quickly with minimal waste.

B. Reduced Contamination

Limits human contact for better hygiene.

C. Lower Labor Costs

Automates processes to reduce workforce needs.

D. Consistent Quality

Ensures even filling and sealing for all tubes.

5. How to Choose the Right Tube Filling and Sealing Machine

Before selecting a Tube Filling and Sealing Machine, consider these factors:

A. Product Type

Lotions, gels, and pastes require different filling mechanisms.

B. Tube Material

Machines must support plastic, aluminum, or laminated tubes.

C. Production Volume

A high-speed Automatic Filling Machine suits large-scale needs.

D. Budget

Find a machine that offers value without compromising quality.

E. Customization Options

Look for machines that allow adjustments in tube size, fill volume, and sealing type.

6. Maintenance Tips for Tube Filling and Sealing Machines

A well-maintained Automatic Filling Machine lasts longer and performs better. Follow these tips:

A. Regular Cleaning

Prevents buildup that can affect performance.

B. Lubrication

Keeps moving parts running smoothly.

C. Routine Inspections

Detects wear and tear early.

D. Software Updates

Ensures efficient and updated operation.

7. The Future of Custom Tube Filling and Sealing Machines

Technology is advancing Tube Filling and Sealing Machines. Future improvements include:

- AI-driven adjustments for better precision.

- Faster processing for increased efficiency.

- Eco-friendly models to reduce energy use.

A custom Tube Filling and Sealing Machine is essential for unique packaging. It ensures precision, efficiency, and consistency. An Automatic Filling Machine improves speed and reduces waste.

Manufacturers should invest in the right machine to enhance production and branding. Customization is key to standing out in a competitive market.