In the world of health and wellness, dietary fiber supplements are growing in popularity. Consumers want cleaner digestive systems, better heart health, and weight control. These benefits are often delivered in capsules made from powdered or granulated fiber.

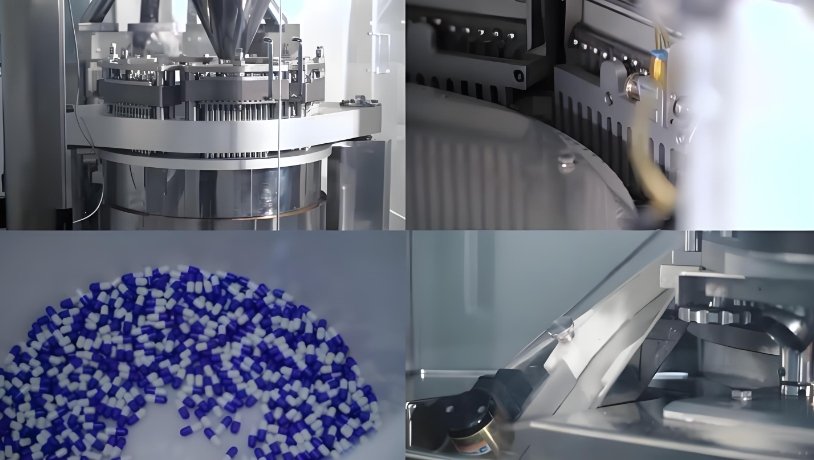

However, filling capsules with dietary fiber can be tricky. The material is often light, fluffy, and tends to stick or clog traditional machines. That’s why many manufacturers now rely on a specialized Capsule Filling Machine built for handling such difficult powders.

In this article, we explore why a high-performance Automatic Filling Machine is essential for fiber-based capsules. We’ll also explain what makes these machines unique, how they work, and what features to look for.

Why Dietary Fiber Needs Special Capsule Equipment

Unlike other active pharmaceutical ingredients (APIs), dietary fiber materials behave differently. They can be coarse, soft, or highly absorbent. Some are sticky. Others are dry and flow poorly. This creates problems when filling capsules.

A basic filler might overfill, underfill, or jam frequently. This can lead to wasted product and lost time. To prevent that, you need a Capsule Filling Machine designed for these challenges. A smart Automatic Filling Machine ensures precise weight, stable output, and hygienic filling — even with hard-to-handle powders.

What Makes the Capsule Filling Machine Special?

The Capsule Filling Machine used for dietary fiber is specially engineered. It has features that control powder flow and allow easy adjustments. These are some of the standout elements:

1. Vacuum Powder Feeder

Fiber material often gets airborne. A vacuum feeder delivers the powder cleanly into the hopper without mess. It also prevents material loss.

2. Dust Extraction System

Fine fiber particles can create a dusty environment. The Capsule Filling Machine includes a built-in dust extractor to keep the workspace clean and safe.

3. Tamping Mechanism

Unlike gravity-based fillers, the tamping system compresses fiber powder to form a slug before it enters the capsule. This ensures consistent weight per capsule.

4. Variable Speed Control

The Automatic Filling Machine allows speed adjustment during operation. You can slow it down for coarse powders and speed it up for fine powders.

Advantages of Using an Automatic Filling Machine

Choosing an Automatic Filling Machine over a manual or semi-auto version has many benefits:

✅ Consistent Quality

It delivers the same fill weight in every capsule, reducing product variance.

✅ High Output

You can produce tens of thousands of capsules per hour, ideal for mass-market dietary supplements.

✅ Labor Savings

Fewer workers are needed to run the line, lowering your operational cost.

✅ GMP Compliance

Stainless steel parts and sealed systems ensure hygiene and safety, helping you meet industry standards.

✅ Easy Cleaning

The best machines are designed for fast disassembly and cleaning between batches — critical when dealing with sticky fibers.

Applications of the Capsule Filling Machine

The Capsule Filling Machine isn’t just for psyllium husk. It can handle a wide range of dietary fiber products such as:

- Inulin

- Glucomannan

- Acacia fiber

- Resistant starch

- Oat bran powder

- Apple fiber

Each type has unique flow characteristics. That’s why only a purpose-built Automatic Filling Machine can process them efficiently.

How the Machine Works – Step-by-Step

Here’s how the fiber capsule production process typically works:

- Capsule Separation: The Capsule Filling Machine first separates the cap from the body of each capsule.

- Powder Tamping: Powder is loaded and tamped into the capsule body. Multi-stage tamping ensures accuracy.

- Capsule Closing: The machine reattaches the cap and locks it in place.

- Ejection: Finished capsules are pushed out for collection or packaging.

- Cleaning Cycle: The system flushes powder residues to prepare for the next run.

With smart controls, operators can easily monitor weight, speed, and fill levels on a touchscreen panel.

Choosing the Right Capsule Filling Machine

Before buying, consider these key points:

✅ Output Speed

Smaller brands may need a mid-speed machine (25,000–40,000 caps/hr). Larger companies should look for models up to 90,000 caps/hr.

✅ Capsule Sizes

Ensure your Capsule Filling Machine works with capsule sizes 00, 0, 1, or smaller, depending on your formula.

✅ Tooling Changeover

Quick tooling swaps help when switching between fiber types or capsule sizes.

✅ Cleaning Access

Hinged doors, smooth surfaces, and removable parts simplify the cleaning process.

✅ Support and Training

Choose a supplier who offers after-sales support, operator training, and local service.

A Real Use Case: Scaling a Fiber Supplement Brand

A wellness company in the U.S. launched a natural colon cleanser based on psyllium and oat fiber. Initially, they used manual capsule fillers. But they soon faced these problems:

- Inconsistent capsule weight

- Powder loss and high rejection rates

- Too much labor cost

- Inability to meet growing demand

They upgraded to an industrial-grade Automatic Filling Machine designed for fiber. The results were immediate:

- Output increased by 5×

- Labor cost dropped 40%

- Customer complaints fell to near zero

- They expanded to three more fiber products in just 6 months

This transformation shows how the right Capsule Filling Machine fuels business growth.

Final Words: The Smart Way to Fill Fiber Capsules

Dietary fiber capsules are here to stay. They offer consumers a safe, convenient way to boost health and digestion. But they’re not easy to make—unless you use the right tools.

A specialized Capsule Filling Machine handles fiber powders with confidence. From dusty psyllium to sticky inulin, the machine processes every load smoothly. And when you use an Automatic Filling Machine, you gain speed, hygiene, and efficiency.

If your business involves fiber products, it’s time to invest in a reliable capsule solution. A modern Capsule Filling Machine will help you grow your brand and meet customer demand without sacrificing quality.