Every business has unique requirements. A Beverage Filling Machine should match those needs. Custom designs help achieve the best performance. Tailored machines save time and boost productivity.

This article explores how personalized solutions benefit your operations.

The Importance of Customization

Why Customize?

Off-the-shelf machines may not fit all needs. Customization ensures efficiency. It also avoids wasted resources.

Key Benefits

- Matches production size.

- Handles specific beverage types.

- Adapts to packaging designs.

- Optimizes space usage.

Customization turns challenges into solutions.

Features of Tailored Beverage Filling Machines

1. Adjustable Speed

Custom machines adapt to production changes.

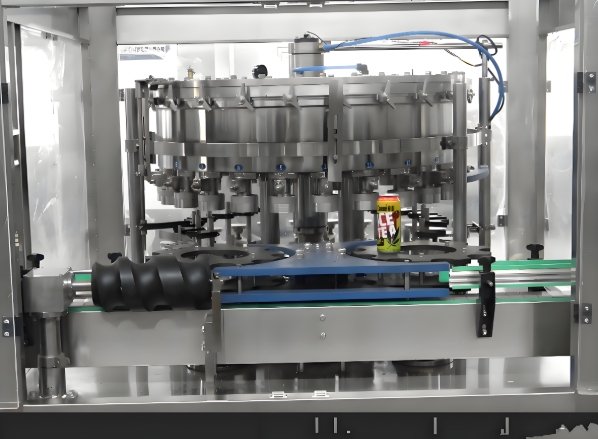

2. Multiple Filling Heads

They speed up operations.

3. Compatibility

Work with different bottle shapes and sizes.

4. Advanced Technology

Include automation for precision.

A custom Automatic Filling Machine delivers these features and more.

Steps to Design Your Perfect Machine

Step 1: Assess Needs

Understand your production requirements.

Step 2: Consult Experts

Work with experienced manufacturers.

Step 3: Choose Features

Pick speed, capacity, and automation levels.

Step 4: Test Prototypes

Ensure the design meets your expectations.

Step 5: Train Staff

Learn to operate the custom machine.

This process ensures a perfect fit for your business.

Industries That Benefit

1. Soft Drink Producers

Machines handle carbonated liquids smoothly.

2. Juice Manufacturers

Precise filling ensures consistent quality.

3. Water Bottling Plants

Large-scale operations need high-speed machines.

4. Craft Beverage Makers

Small machines fit limited spaces.

Each industry needs a tailored Beverage Filling Machine.

Advanced Custom Features

1. Automation Integration

An Automatic Filling Machine uses smart systems.

2. Remote Monitoring

Track performance from anywhere.

3. Energy Efficiency

Lower operating costs.

4. Hygiene Controls

Ensure beverage safety.

These features enhance functionality and reliability.

Materials That Suit Your Needs

1. Stainless Steel

Durable and rust-resistant.

2. Food-Grade Plastics

Safe for beverages.

3. Aluminum

Lightweight but sturdy.

Materials affect machine performance and lifespan.

Maintenance for Custom Machines

- Regular cleaning prevents blockages.

- Lubricate parts to reduce wear.

- Inspect for damages weekly.

- Update software for automated systems.

Proper care ensures long-lasting performance.

Cost of Customization

Factors Affecting Cost:

- Production scale.

- Additional features.

- Type of materials.

- Complexity of design.

While custom machines cost more upfront, they save money long-term.

Case Study: Customization Success

A small juice company struggled with standard machines. They opted for a custom Beverage Filling Machine.

Results:

- Production doubled in six months.

- Wastage reduced by 30%.

- Machine met all unique requirements.

Customization transformed their business.

Challenges in Customization

- High initial investment.

- Longer lead times.

- Need for expert support.

Choosing the right manufacturer solves these challenges.

How to Choose the Best Manufacturer

1. Industry Experience

Work with proven experts.

2. Strong Reputation

Check reviews and past projects.

3. Quality Assurance

Ensure materials and features meet standards.

4. Post-Sale Support

Reliable service is essential.

A good manufacturer makes customization smooth.

Innovations in Custom Machines

1. Smart Sensors

Detect errors early.

2. AI Integration

Adjust operations automatically.

3. Modular Designs

Replace parts easily.

These innovations improve machine performance.

Future of Custom Beverage Filling Machines

- Eco-friendly designs will rise.

- Machines will use less energy.

- AI will enhance precision further.

The future brings exciting possibilities.

Custom Beverage Filling Machines offer unmatched advantages. They save time, improve quality, and meet unique needs. Adding automation through an Automatic Filling Machine enhances efficiency further.

Choose a trusted manufacturer to guide the process. Invest in a machine designed for your business. It’s a decision that guarantees success.