Filling machines are essential for industries handling viscous liquids. These machines streamline the process of filling products like honey, creams, sauces, and gels into containers. To maximize efficiency, following best practices is key.

This article will explain the best practices for viscous liquid filling machines. Whether using an automatic filling machine or a manual one, these tips can enhance productivity.

1. Understanding Viscous Liquid Filling Machines

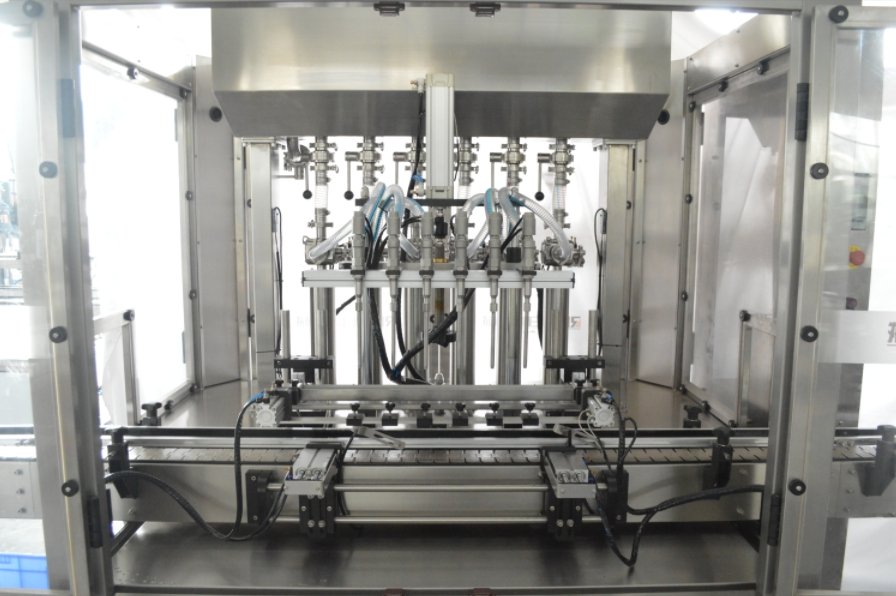

A viscous liquid filling machine is designed to handle thick products. These products don’t flow easily and need a machine capable of accurately filling containers. Automatic filling machines are the most efficient for high-volume production.

Viscous liquids require specific techniques for smooth filling. The right equipment, paired with proper settings, ensures accurate results.

2. Selecting the Right Machine

Choosing the correct machine for your production line is crucial. Some viscous liquid filling machines use piston fillers. These machines are ideal for thick liquids, as they use pressure to push the product into containers.

- Automatic Filling Machine

An automatic filling machine is the best option for high-speed production. These machines can fill large quantities with minimal operator involvement. - Semi-Automatic Machine

For smaller operations, semi-automatic machines can be a cost-effective option. However, they may require more manual intervention.

Ensure the machine you choose matches the viscosity of your product. Thicker liquids may require machines with higher pressure settings.

3. Temperature Control

Temperature plays a significant role in filling viscous liquids. Some thick liquids become more fluid at higher temperatures. In these cases, heating the product can make it easier to fill containers.

- Pre-heating the Liquid

Heating the liquid before filling can reduce its viscosity. This ensures smoother flow and reduces clogs in the machine. - Heated Filling Systems

Some viscous liquid filling machines come with built-in heating systems. These machines maintain a consistent temperature, ensuring optimal filling conditions.

By managing temperature effectively, you can prevent issues like inconsistent fill levels or product clogging.

4. Nozzle Selection and Adjustment

Nozzles are a critical part of the filling machine. They control the flow of the liquid into the container. For viscous liquids, using the right nozzle is essential.

- Larger Nozzles

Thicker liquids need wider nozzles to flow smoothly. A small nozzle may cause blockages, reducing efficiency. - Adjustable Nozzles

Some automatic filling machines come with adjustable nozzles. These allow operators to fine-tune the flow based on the product’s viscosity. - Nozzle Position

For accurate filling, the nozzle should be positioned close to the container’s opening. This reduces splashing and ensures consistent fill levels.

5. Optimal Filling Speed

Filling speed is another factor that affects accuracy. Viscous liquids move more slowly, so filling machines need to be calibrated for this.

- Slow Filling for Precision

Slower filling speeds are often better for thick liquids. This reduces air pockets and ensures an even fill. - Adjusting Automatic Machines

Automatic filling machines can be adjusted to match the product’s flow rate. Slowing down the machine may be necessary to maintain accuracy.

By optimizing the filling speed, you ensure that each container receives the correct amount of product, improving overall quality.

6. Regular Maintenance and Cleaning

Maintaining your filling machine is critical for ensuring consistent performance. Viscous liquids can easily cause buildup inside the machine.

- Frequent Cleaning

Clean the machine regularly to prevent clogs. Thick liquids can stick to the machine’s interior, affecting the filling process. - Inspect Seals and Gaskets

Viscous liquids put more strain on seals and gaskets. Check these parts frequently for wear and tear, and replace them as needed. - Lubrication

Keep moving parts well-lubricated to avoid breakdowns. This is especially important in machines handling thick liquids, which create more friction.

Proper maintenance extends the life of your filling machine and ensures it operates at peak efficiency.

7. Avoiding Air Pockets

Air pockets can be a common problem when filling thick liquids. These pockets create voids in the container, leading to inaccurate fill levels.

- Bottom-Up Filling

Many viscous liquid filling machines use bottom-up filling techniques. The nozzle starts near the bottom of the container and rises as the liquid fills. This reduces air bubbles and ensures a smooth fill. - Piston Filling Machines

Piston fillers are ideal for minimizing air pockets. These machines push the product into the container under pressure, eliminating voids.

By taking steps to avoid air pockets, you improve the accuracy and quality of your filled products.

8. Consistency in Product Flow

Ensuring a consistent flow of viscous liquids is essential for achieving uniform fill levels. Variations in flow can lead to overfilling or underfilling.

- Agitators

Some automatic filling machines come with agitators in the hopper. These keep the product moving, preventing clumping or uneven flow. - Pressure Control

Machines with pressure control systems can maintain a steady flow, ensuring each container is filled with the same amount of product.

By focusing on consistency, you reduce product waste and ensure a higher quality fill.

9. Choosing the Right Containers

The type of container used affects how well viscous liquids are filled. Containers with narrow openings can make filling more difficult, while wide-mouth containers are easier to fill.

- Wide-Mouth Containers

For thick liquids, containers with wider openings work best. They allow the liquid to flow in smoothly without causing overflow. - Sturdy Containers

Viscous liquids can be heavy, so the container needs to be durable. Thin or weak containers may collapse under the weight of the product.

By selecting the right containers, you can optimize your filling process and reduce the risk of product loss.

10. Automation for High-Volume Production

Automation is key for businesses handling large volumes of viscous liquids. An automatic filling machine can fill containers quickly and accurately, minimizing human error.

- Automatic Filling Machine Benefits

Automatic machines improve production speed, reduce labor costs, and ensure consistency in every container. These machines are particularly useful for businesses handling thick liquids in large quantities. - Integration with Other Systems

Automatic filling machines can be integrated with other equipment like capping and labeling machines. This streamlines the entire production process.

For businesses looking to scale their operations, investing in automation is a smart choice.

Viscous liquid filling machines are essential for industries handling thick products. By following best practices, you can optimize your filling machine’s performance. Choose the right machine, control the temperature, and use proper nozzles for accurate results. Maintenance, air pocket prevention, and container selection are also critical factors.

For high-volume operations, automatic filling machines offer the best efficiency and accuracy. They reduce labor, improve product consistency, and speed up production. By applying these best practices, your business can enhance the performance of its filling machine and improve product quality.