The Tube Filling and Sealing Machine has come a long way. It plays a critical role in modern production. From its origins to today’s advanced Automatic Filling Machines, the journey has been remarkable. This article explores the evolution of these machines.

1. The Early Days of Tube Filling Machines

In the early 20th century, industries manually filled and sealed tubes. This process was slow. It required significant labor. Inaccuracies were common. These challenges drove the need for automation.

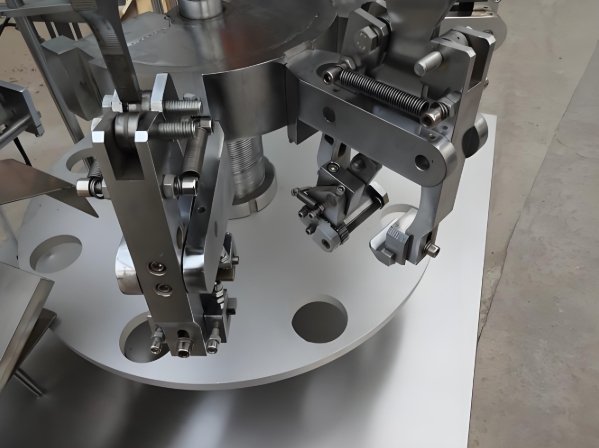

The first Tube Filling and Sealing Machine was basic. It used simple mechanical systems. It could handle only a small number of tubes per hour. Yet, it was a major improvement over manual labor.

2. The Introduction of Automation

The mid-20th century brought automation. Early Automatic Filling Machines could fill and seal tubes without manual intervention. These machines improved speed. They also reduced errors.

Industries adopted these machines quickly. They became essential in cosmetics, pharmaceuticals, and food production. Automation changed the way factories operated.

3. Key Innovations Over Time

Advancements in technology have shaped modern machines. Here are some milestones:

- Precision Filling Systems: Early machines lacked accuracy. Modern systems fill tubes with exact quantities.

- Sealing Improvements: Initial machines used simple clamps. Today, machines use advanced sealing methods like heat or ultrasonic technology.

- Material Compatibility: Older machines could handle limited materials. Modern machines handle plastic, aluminum, and laminate tubes.

- High-Speed Operations: Early machines were slow. Modern Automatic Filling Machines process hundreds of tubes per hour.

4. The Role of Electronics and Sensors

The introduction of electronics revolutionized the industry. Sensors now detect tube positioning. They ensure accurate filling and sealing. Machines stop automatically if errors occur.

Digital controls simplify machine operation. Operators can adjust settings with ease. This technology has improved efficiency.

5. Modern-Day Features

Modern Tube Filling and Sealing Machines come with advanced features. These include:

- Touchscreen Interfaces: Easy to use and program.

- Automatic Tube Feeding: Machines pick and place tubes without manual help.

- Multi-Product Handling: They handle liquids, creams, and gels effortlessly.

- Compact Designs: Space-saving models are now common.

These features make machines reliable and efficient.

6. Industry-Specific Adaptations

Different industries have unique needs. Machines have evolved to meet these demands.

Cosmetics Industry

Machines handle sensitive creams and lotions. They ensure perfect seals for attractive packaging.

Pharmaceutical Industry

Precision is crucial. Machines ensure accurate filling of medicated ointments.

Food Industry

They handle sauces, pastes, and other consumables. Sealed tubes preserve freshness.

Chemical Industry

Machines fill adhesives and greases. They ensure safe storage and transport.

7. Benefits of Modern Machines

Modern Automatic Filling Machines offer many benefits. These include:

- Speed: High output boosts production.

- Consistency: Every tube is identical.

- Hygiene: Machines maintain clean filling environments.

- Flexibility: They adapt to different tube sizes and materials.

These advantages make them indispensable for industries.

8. Environmental Considerations

Sustainability is now a priority. Modern machines use eco-friendly materials. They minimize waste during production. Energy-efficient designs reduce power consumption.

Some machines also recycle unused materials. These innovations support greener practices.

9. The Future of Tube Filling Machines

The future looks promising. Artificial intelligence will play a key role. AI will enhance machine learning capabilities. Machines will predict maintenance needs. They will optimize performance.

The Internet of Things (IoT) will connect machines. Operators will monitor systems remotely. This will reduce downtime.

Sustainability will also remain a focus. More machines will use biodegradable materials. Factories will adopt cleaner production methods.

10. Choosing the Right Machine

Selecting the right Tube Filling and Sealing Machine is essential. Consider these factors:

- Production Volume: Choose a machine that meets your output needs.

- Product Type: Ensure the machine suits your product consistency.

- Budget: Modern machines come in various price ranges.

- Maintenance Needs: Low-maintenance models save time and money.

Investing in the right machine ensures long-term success.

The Tube Filling and Sealing Machine has transformed over the years. From manual operations to advanced Automatic Filling Machines, the evolution is impressive. Modern machines improve speed, accuracy, and efficiency.

They cater to industries like cosmetics, food, and pharmaceuticals. Future innovations promise even greater advancements. Investing in these machines is essential for competitive success. Choose the best machine to meet your industrial needs today.