The demand for filling machines in manufacturing continues to grow. From food and beverages to cleaning products, filling machines play a vital role. However, like all industrial equipment, they have an environmental impact. The energy used, waste generated, and materials processed can all affect the planet. Understanding these impacts is crucial for creating more sustainable practices.

How Filling Machines Affect the Environment

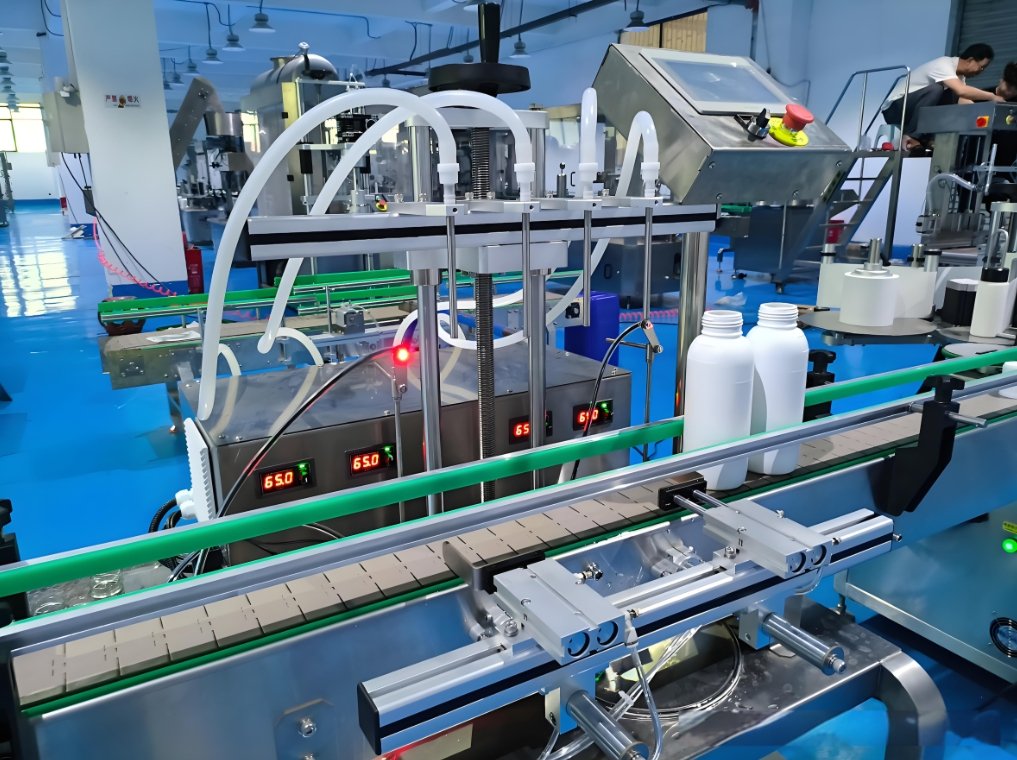

Filling machines consume energy, use water, and produce waste. Their design, maintenance, and operation contribute to their overall environmental footprint. In particular, automatic filling machines often operate continuously, increasing their energy demands.

- Energy Consumption Most filling machines run on electricity. High-energy use impacts both the environment and operating costs. Automatic filling machines, in particular, may require more power due to their continuous operations.

- Water Usage Some filling machines require water, especially in food production. Water is used to rinse or sanitize containers. However, excessive water use can strain local resources and increase the environmental footprint.

- Waste Generation Machines create waste, including rejected materials, packaging waste, and product spillage. Over time, this waste can accumulate, impacting both cost and environmental health.

- Emissions The production and disposal of filling machines also generate emissions. Emissions occur from metal processing, plastic production, and other manufacturing steps. These can contribute to pollution if not managed correctly.

Sustainable Choices in Filling Machine Design

Manufacturers can reduce the environmental impact of filling machines. By focusing on sustainable design, they minimize waste, energy use, and emissions. Many filling machine producers now integrate eco-friendly features.

- Energy-Efficient Motors Newer filling machines use energy-efficient motors. These motors use less power, reducing emissions. They also help companies save on electricity, benefiting both the environment and operational costs.

- Smart Systems and Automation Modern filling machines feature smart sensors and automated controls. These systems optimize energy use, adjusting based on real-time needs. This approach reduces wasted energy, lowering the machine’s footprint.

- Recyclable Materials Filling machines made with recyclable or reusable materials contribute to sustainability. Stainless steel and food-grade plastics can be recycled, helping to reduce landfill waste.

- Improved Filtration Systems Machines with advanced filtration systems minimize water use. Some filling machines recycle rinse water, reducing the demand for fresh water. This is especially important in areas with water scarcity.

Reducing Waste in Filling Machine Operations

Waste reduction is essential for environmentally friendly production. Companies that manage waste effectively improve sustainability and reduce costs. Here are ways to minimize waste in filling machine operations:

- Accurate Fill Levels Overfilling creates product waste. Calibrating machines for precise fills prevents excess waste. This approach reduces the amount of product lost in each batch.

- Efficient Packaging Using minimal packaging decreases waste. Choose packaging materials that are recyclable or biodegradable. These changes minimize the impact on landfills.

- Maintenance and Calibration Regular maintenance keeps filling machines efficient. Machines that are well-maintained use less energy and produce less waste. Calibration also ensures each fill is accurate, preventing unnecessary loss.

- Proper Disposal of Waste Separate waste streams and recycle where possible. Many filling machines now have waste collection systems that reduce spillage and capture waste materials.

The Role of Automatic Filling Machines in Eco-Friendly Production

Automatic filling machines are essential for high-volume production. However, they can contribute to significant energy use. Sustainable practices can make these machines greener and more efficient.

- Reducing Downtime Automatic filling machines that run continuously can use up more energy. Reducing downtime helps save energy. Companies can schedule operations during off-peak hours to reduce their environmental impact.

- Integration with Green Technology Automatic machines can integrate with renewable energy sources. Solar or wind power can support energy needs, reducing reliance on traditional energy. This integration lowers emissions and operational costs.

- Smart Automation for Better Efficiency Automation features allow machines to operate only when needed. Sensors detect container presence and control fill levels, reducing energy waste. This “smart” operation uses energy efficiently, benefiting the environment.

- Temperature Control Some products require heated fills. Efficient temperature control can lower energy needs. Machines with insulation or smart temperature management use less power, making the process more sustainable.

Sustainable Practices in Filling Machine Manufacturing

The environmental impact of filling machines goes beyond their daily operations. The manufacturing process also plays a role. By adopting sustainable practices, manufacturers can lessen their machines’ impact from the start.

- Use of Recycled Materials Some filling machine manufacturers use recycled steel and plastics. This practice reduces the need for new resources. It also minimizes waste and reduces emissions during production.

- Waste Reduction in Production Efficient manufacturing processes create less waste. Some manufacturers use precision cutting and molding, reducing the amount of scrap produced.

- Energy-Efficient Facilities Many filling machine manufacturers invest in energy-efficient facilities. Using LED lighting, automated climate control, and green energy, they cut emissions significantly.

- Eco-Friendly Packaging Packaging for shipping machines can be wasteful. Many companies now use recycled or minimal packaging, reducing their impact on the environment.

Benefits of Sustainable Filling Machine Practices

Adopting eco-friendly practices for filling machines offers several benefits. It reduces environmental impact, conserves resources, and can lead to cost savings.

- Cost Reduction Sustainable practices can reduce operational costs. Energy-efficient machines use less electricity, lowering energy bills. Minimizing waste also saves money by reducing material costs.

- Improved Brand Image Eco-conscious consumers value companies that care about sustainability. Using sustainable filling machines can enhance brand image. It shows a commitment to the environment and responsible production.

- Regulatory Compliance Governments increasingly regulate energy use and waste management. Sustainable filling machines help companies comply with environmental regulations. This avoids fines and ensures smooth operations.

- Employee Satisfaction Employees value working for eco-friendly companies. Sustainable practices can boost morale, leading to higher productivity.

- Environmental Protection Reducing waste, conserving energy, and using recycled materials all protect the environment. Sustainable practices benefit everyone, from the company to the global community.

Future Trends in Eco-Friendly Filling Machines

As sustainability gains importance, filling machines are evolving. Manufacturers are focusing on new technologies and practices that make machines greener.

- Renewable Energy Integration More companies are powering filling machines with renewable energy. Solar, wind, and even geothermal energy may become standard.

- Biodegradable Packaging Materials Packaging materials continue to improve. Machines that handle biodegradable packaging reduce waste. This trend aligns with the demand for more sustainable consumer goods.

- Carbon-Neutral Manufacturing Some companies aim to achieve carbon neutrality. Carbon-neutral filling machine manufacturing means offsetting emissions through sustainable practices.

- Smarter Automation Automation will continue to advance. Filling machines that learn from data can adjust energy use, fill levels, and operational speed. These improvements will enhance efficiency and reduce waste.

Filling machines play an essential role in many industries. However, their environmental impact is undeniable. Through energy-efficient designs, waste reduction, and sustainable manufacturing, companies can lower their machines’ environmental footprint.

Automatic filling machines bring speed and consistency, but they must be eco-friendly. By adopting smart technology, optimizing resources, and integrating renewable energy, businesses can produce greener products. Sustainable filling machine practices benefit the environment, reduce costs, and align with eco-conscious consumer values. As technology advances, filling machines will continue to become even more sustainable, paving the way for a cleaner, greener future.