In today’s fast-paced packaging industry, accuracy and efficiency are essential. This is especially true when labeling round bottles for beverages, cosmetics, pharmaceuticals, and more. A high-performance Labeling Machine with sensor detection ensures each label is placed with perfect alignment—every time. When paired with an Automatic Filling Machine, you get a complete packaging solution that minimizes errors, maximizes speed, and delivers top-quality results.

This article explores how sensor-equipped round bottle Labeling Machines work, their advantages, and why they are a perfect match for any Automatic Filling Machine.

Why Round Bottles Need Specialized Labeling

Round bottles are common across many industries. They’re used for water, juice, shampoo, essential oils, sauces, and medications. But labeling them comes with challenges. If the label is even slightly misaligned, it becomes visually unappealing or unreadable. This is where a Labeling Machine with sensor detection proves invaluable.

Sensor detection ensures the label is applied in the correct position on every bottle, regardless of minor variations in size, position, or speed. It guarantees consistency, which is crucial for branding and compliance.

How Sensor Detection Works

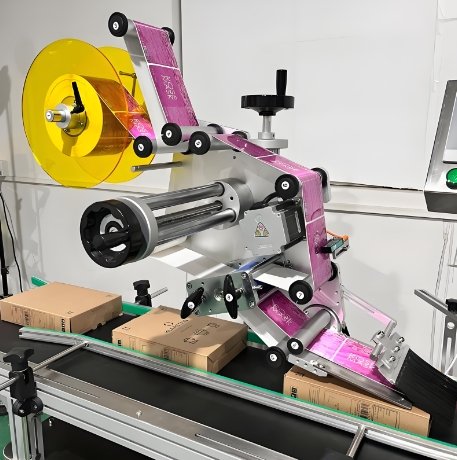

Modern Labeling Machines use optical or photoelectric sensors to detect the exact position of each bottle on the conveyor. The sensor triggers the label dispenser at precisely the right moment, ensuring accurate application.

Here’s a step-by-step overview:

- Bottle Detection: A sensor detects the approaching round bottle.

- Label Readiness: The machine prepares the label to be applied.

- Synchronized Application: As the bottle passes the applicator, the label is rolled onto the surface using a wrap-around belt or roller.

- Verification: Some Labeling Machines include a second sensor to confirm label placement.

This integration dramatically improves label accuracy, even at high speeds.

Seamless Integration with an Automatic Filling Machine

A Labeling Machine with sensor detection complements any Automatic Filling Machine perfectly. Together, they form a continuous, automated line that handles:

- Filling bottles with precise liquid volumes

- Capping and sealing

- Labeling with exact positioning

This integration reduces labor costs, minimizes human error, and increases throughput. With communication between machines managed by a PLC system, both units can adapt speeds in real time, preventing bottlenecks or downtime.

Key Benefits of a Sensor-Equipped Labeling Machine

✅ Precision Labeling on Round Surfaces

Sensor detection ensures perfect alignment on curved bottles, eliminating wrinkles or crooked labels.

✅ High-Speed Operation

With the ability to label over 100 bottles per minute, these machines match the pace of any Automatic Filling Machine.

✅ Adaptability to Different Bottles

Change bottle sizes or label formats quickly with minimal setup time.

✅ Reduced Waste

No more wasted labels due to misapplication. Fewer rejected bottles.

✅ Minimal Operator Intervention

The system monitors itself and alerts the operator only when necessary.

Industries That Benefit from Sensor-Equipped Labeling Machines

- Food and Beverage: For water, juice, sauces, dressings

- Cosmetics: Shampoo, body wash, facial oils

- Pharmaceuticals: Medicine bottles, herbal supplements

- Chemicals: Detergents, cleaners, lab reagents

In each case, the bottles must first be filled with precision. That’s where the Automatic Filling Machine comes in—measuring, filling, and handing the product to the labeling station.

Core Features to Look For

When selecting a Labeling Machine for round bottles with sensor detection, consider the following features:

✔️ Adjustable Conveyor Speed

Allows smooth handoff from the Automatic Filling Machine to the labeler.

✔️ Wrap-Around Labeling

Ensures 360° label coverage on cylindrical bottles.

✔️ Label Position Adjustments

Fine-tune label height, angle, and alignment with ease.

✔️ Label Sensors

Detect transparent or opaque labels with high precision.

✔️ User-Friendly Touchscreen Interface

Operators can save settings, run diagnostics, and change formats without complex commands.

Sensor Technology Types

There are different types of sensors used in Labeling Machines. Each serves a specific purpose:

- Ultrasonic Sensors: Ideal for transparent labels where standard sensors may fail

- Photoelectric Sensors: Detect contrast between the bottle and label

- Fiber-Optic Sensors: Provide precise positioning on reflective or dark surfaces

Choosing the right sensor ensures your machine works flawlessly with your packaging materials.

Labeling Machine and Automatic Filling Machine Synergy

When combined, the Labeling Machine and Automatic Filling Machine create a powerful, automated system. Here’s how they synchronize:

- The Automatic Filling Machine fills the exact product quantity into each round bottle.

- Bottles are transported to the labeling station via a conveyor.

- Sensors on the Labeling Machine detect bottle arrival and start labeling.

- The two systems communicate constantly to ensure speed and flow consistency.

This eliminates bottlenecks and boosts productivity.

Return on Investment (ROI)

Investing in a sensor-driven Labeling Machine delivers fast returns:

- Fewer labor hours required per shift

- Lower rejection rates due to mislabeling

- Faster production timelines

- Increased customer satisfaction with perfectly labeled products

When paired with a reliable Automatic Filling Machine, this equipment transforms a basic production line into a high-efficiency operation.

Common Applications in Real-World Packaging

Let’s look at a real-world example:

Company A, a beverage manufacturer, struggled with inconsistent labeling on its juice bottles. After adding a sensor-equipped Labeling Machine to their Automatic Filling Machine line, they saw a 30% increase in labeling speed and a 90% reduction in misaligned labels. The improvement enhanced their product image and reduced costs.

Environmental Considerations

Many manufacturers now use eco-friendly labels or biodegradable adhesives. Modern Labeling Machines support these materials without sacrificing speed or accuracy.

Paired with an energy-efficient Automatic Filling Machine, this setup also reduces the environmental footprint of your production line.

Conclusion

A Labeling Machine with sensor detection is a must-have for any company that packages round bottles. It ensures fast, accurate, and professional labeling. When integrated with an Automatic Filling Machine, it creates a fully automated system that improves speed, quality, and consistency.

Whether you’re in food and beverage, cosmetics, pharmaceuticals, or chemicals, this technology will elevate your packaging line. Make the smart choice—invest in sensor-driven automation and keep your product presentation as strong as the product itself.