Paper Box Packaging Machine: Efficient and Eco-Friendly

A paper box packaging machine is essential for modern packaging needs. It automates the process of forming, filling, and sealing paper boxes. This machine is fast, eco-friendly, and reliable. It helps businesses package products with ease.

How the Paper Box Packaging Machines Works

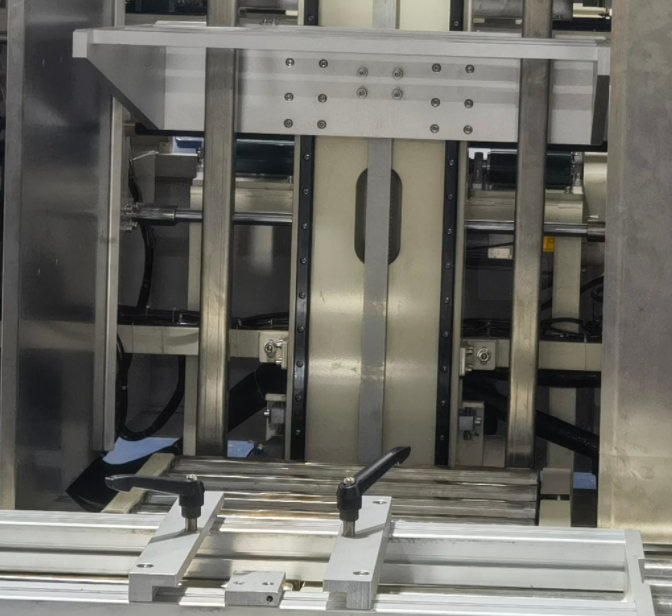

The paper box packaging machines starts by folding flat paperboard into box shapes. Once the boxes are formed, the machine fills them with products. Finally, it seals the boxes securely, ready for shipping or display. The entire process is automated, reducing the need for manual labor.

Key Features of the Paper Box Packaging Machines

This machine is highly flexible. It can handle various box sizes and shapes. Whether small cartons or large boxes, the machine adjusts easily. It also operates at high speeds, making it perfect for high-demand production lines. The paper box packaging machines ensures precision in every step. This reduces the risk of errors.

Applications of the Paper Box Packaging Machines

Applications of the Paper Box Packaging Machine

Food Industry: Manufacturers use this equipment to package cereals, snacks, frozen foods, and dry goods. Specifically, the machine creates tight seals to maintain freshness and protect products from contamination.

Cosmetics Sector: This system handles items like soaps, creams, lotions, and perfumes. Furthermore, it provides boxes with a clean, polished, and professional appearance suitable for retail shelves.

Pharmaceutical Industry: These units package medicines, tablets, supplements, and medical supplies. In doing so, the technology ensures proper protection, hygiene, and safe handling.

Retail & Consumer Goods: Companies widely use these machines to package electronics, clothing, accessories, and toys. Consequently, the system prepares products efficiently for shipping or store display.

Benefits of Using a Paper Box Packaging Machine

Faster Production: The system automates the entire packaging process. Therefore, businesses package more products in significantly less time.

Reduced Labor Costs: Automation minimizes manual work. Moreover, it lowers overhead expenses and reduces workplace injuries.

Consistent Packaging Quality: The machine forms, fills, and seals boxes with high precision. Thus, the technology improves both product appearance and reliability.

Eco-Friendly Operation: These machines utilize recyclable materials. Accordingly, they help companies reduce their environmental impact.

Professional Finish: The hardware ensures clean edges and accurate folds. Finally, this precision creates perfect seals for premium product presentation.

Why Choose Paper Box Packaging Machines?

A paper box packaging machine represents a smart investment for companies aiming to improve speed, efficiency, and packaging quality. Specifically, it streamlines production while delivering professional, eco-friendly packaging results. As global demand for sustainable solutions grows, manufacturers often consult international standards for paperboard packaging to ensure material durability and recyclability.

Operators can integrate the machine seamlessly into existing production lines, thereby enhancing workflow without major adjustments. Furthermore, this versatility across industries such as food, cosmetics, pharmaceuticals, and retail ensures that the system secures products attractively. For instance, during medical applications, these systems must strictly adhere to pharmaceutical packaging regulations to maintain safety and compliance. Once the boxes are ready, many facilities integrate a palletizing packaging machine to stack and prepare the final products for bulk transport efficiently.

In conclusion, these machines boost productivity, reduce costs, and upgrade packaging standards. Therefore, they serve as an essential tool for modern manufacturing. To ensure your system remains at peak performance, our Packaging Machine Service provides expert technical support and preventative maintenance.