Efficiency and traceability are critical in today’s packaging lines. Businesses must ensure that every product is labeled, coded, and ready for sale or shipment. That’s why using a Labeling Machine with inkjet coding integration is a powerful step forward. When combined with an Automatic Filling Machine, this setup turns your line into a fast, flexible, and fully automated packaging system.

In this article, we’ll explore how an integrated Labeling Machine and inkjet coder work, their benefits, and how to set them up alongside an Automatic Filling Machine to streamline your packaging operation.

Why Combine Labeling and Inkjet Coding?

Traditionally, labeling and coding were done in two separate stages. But modern production demands speed and accuracy. That’s where the integration of inkjet coding into a Labeling Machine proves beneficial.

Inkjet coding applies variable data—such as expiration dates, batch numbers, and barcodes—directly onto labels or containers. When you integrate it into a Labeling Machine, coding occurs simultaneously with label application. This saves time, reduces alignment errors, and increases throughput.

When your Automatic Filling Machine feeds filled containers into this setup, the process becomes seamless—filling, labeling, and coding in one continuous line.

How It Works: Labeling and Coding in One System

Here’s how an integrated setup functions step-by-step:

- Automatic Filling Machine fills containers (bottles, jars, or cans) with product.

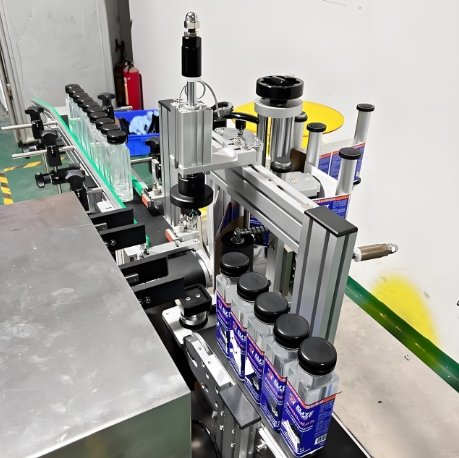

- Filled containers move on a conveyor to the Labeling Machine.

- The Labeling Machine applies a label to each container.

- As the label is applied, the inkjet coder prints the required information—such as date or lot code—either on the label or directly on the container.

- Coded and labeled products move down the line, ready for packing.

This real-time labeling and coding eliminates delays and minimizes human error.

Key Benefits of Labeling Machine with Inkjet Integration

✅ Reduced Downtime

The combined Labeling Machine and inkjet coder eliminate the need for separate systems. This results in faster operations and fewer bottlenecks.

✅ Precise Coding

Since coding happens during the labeling process, placement is exact. No misaligned or unreadable codes.

✅ Full Line Automation

When this system is paired with an Automatic Filling Machine, your production line becomes highly automated. From filling to labeling to coding—no manual intervention is needed.

✅ Compliance and Traceability

Regulations in food, pharmaceuticals, and cosmetics often require traceable product information. This system ensures every item is properly coded.

✅ Scalability

Whether you label 1,000 or 10,000 units per hour, the integration keeps pace. You can scale up production without changing equipment.

Ideal Applications for Inkjet + Labeling Integration

Industries across sectors benefit from this powerful combination:

- Food & Beverage – Bottles, jars, and cartons labeled and coded for freshness.

- Pharmaceuticals – Lot numbers and expiry dates clearly printed on every label.

- Cosmetics – Smooth label applications with lot codes for quality assurance.

- Household Chemicals – Label resistant to moisture and chemicals, with inkjet coding for safety and tracking.

- Nutraceuticals & Supplements – Small containers labeled and coded at high speeds.

When paired with an Automatic Filling Machine, these industries benefit from unmatched efficiency and accuracy.

Features to Look for in a Labeling Machine with Inkjet Coding

To get the most from your system, choose a Labeling Machine with the following features:

✔️ Inkjet Compatibility

Ensure it supports integration with leading inkjet brands. Some machines come with mounting brackets and electronic syncing options built-in.

✔️ High-Speed Label Application

The labeling speed should match or exceed your Automatic Filling Machine output to prevent backup.

✔️ Smart Sensors

Modern machines include sensors that detect product position and label gaps for precise placement and printing.

✔️ Touchscreen Interface

A user-friendly control panel allows operators to adjust print settings, label types, and product sizes with ease.

✔️ Durable Build

Stainless steel construction ensures hygiene and long-term reliability, especially when used in conjunction with an Automatic Filling Machine handling liquids.

Setup and Maintenance Tips

Installing a labeling and inkjet system is straightforward, but best results come from proper setup and care.

🔧 Setup

- Ensure synchronization between the Labeling Machine and Automatic Filling Machine.

- Mount the inkjet printhead at the correct distance and angle.

- Test with sample containers and labels before full production.

🧽 Maintenance

- Clean inkjet nozzles daily to prevent clogging.

- Check label feed rollers for wear.

- Keep sensors free of dust and residue.

Preventative maintenance increases uptime and reduces coding errors.

Integrating with Your Automatic Filling Machine

When your Labeling Machine is linked with your Automatic Filling Machine, the entire line runs like clockwork. Here’s how to ensure perfect integration:

- Match Speeds – The labeler and inkjet coder should match the bottle output of your Automatic Filling Machine.

- Align Conveyors – Ensure bottles travel smoothly from the filler to the labeler without jams.

- Use PLC Controls – Centralized control systems can synchronize all components for smooth operation.

- Design for Flexibility – Choose modular machines that accommodate different bottle sizes, fill levels, and label types.

By designing with integration in mind, you maximize your ROI and ensure seamless packaging.

Conclusion: A Smart Upgrade for Modern Production

Investing in a Labeling Machine with inkjet coding integration is one of the smartest upgrades you can make to your packaging line. When paired with an efficient Automatic Filling Machine, you create a fully automated, high-performance solution that handles filling, labeling, and coding in a single flow.

This setup boosts your output, ensures code compliance, and enhances your brand’s appearance on the shelf. It’s perfect for any industry where speed, accuracy, and traceability are crucial.

Take the next step toward smarter production. Choose a high-quality Labeling Machine, integrate inkjet coding, and connect it to your Automatic Filling Machine for a complete end-to-end solution.