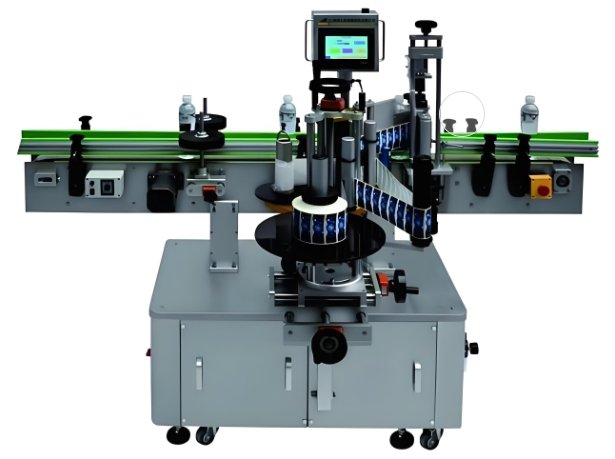

Flexible packaging has changed the way businesses present and protect products. It’s cost-effective, lightweight, and great for storing liquids, powders, snacks, or healthcare items. But with these advantages come challenges in labeling. You need a Labeling Machine that can handle flexible, non-rigid surfaces while maintaining high speed and accuracy.

When integrated with an Automatic Filling Machine, a Labeling Machine can drastically improve your production line’s output and consistency. In this article, we explore everything you need to know about labeling flexible packaging—from machine design to practical applications and buying tips.

Understanding Flexible Packaging

Flexible packaging includes pouches, sachets, wraps, bags, and even squeeze tubes. These materials bend, move, and change shape during handling. That makes it harder to apply a label without wrinkling, bubbling, or misalignment.

A high-quality Labeling Machine solves this by using special sensors, precise rollers, and support systems to gently apply labels with perfect accuracy. It ensures every product leaves your line looking professional and on-brand.

When you use flexible packaging in combination with an Automatic Filling Machine, you get fast filling, reliable sealing, and smooth labeling all in one automated line.

Why Use a Specialized Labeling Machine for Flexible Materials

1. Surface Adaptability

Unlike rigid containers, flexible packaging doesn’t hold its shape on its own. A regular Labeling Machine might apply labels unevenly or create wrinkles. Machines built for flexible materials apply even pressure, control bag movement, and hold the material in place while labeling.

2. High-Speed Processing

Flexible packaging often supports high-volume production. A reliable Labeling Machine keeps up with the pace, applying labels quickly and without error. When matched with a fast Automatic Filling Machine, your line becomes more productive and cost-effective.

3. Precision Sensors

Modern Labeling Machines use photoelectric or ultrasonic sensors that detect the product’s edge, shape, and size. This allows for exact label placement, even if the package is slightly curved or shifting during movement.

4. Adjustable Settings

You can easily switch between packaging sizes and shapes. Whether you’re labeling a small pouch or a large refill pack, the machine adjusts to maintain quality and efficiency.

Common Industries Using Flexible Packaging and Labeling Machines

Many sectors now rely on flexible packaging, and a compatible Labeling Machine is essential for each of them. Here’s where this setup shines:

- Food and Snacks: Chips, dried fruits, and sauces in pouches

- Beverages: Drink pouches, energy gels

- Health & Beauty: Shampoo sachets, lotion pouches

- Pharmaceuticals: Single-dose medicine bags

- Pet Care: Treat pouches, soft food packs

- Household Cleaners: Refill packs for detergents or sprays

All of these use both an Automatic Filling Machine and a Labeling Machine to complete their packaging lines.

How the Process Works: Filling to Labeling

A typical packaging line using flexible materials starts with an Automatic Filling Machine, which:

- Opens the bag or pouch

- Fills it with the product (liquid, powder, or solid)

- Seals the pouch for protection

Next, the product moves to the Labeling Machine, where:

- The packaging is aligned using guides or conveyors

- Sensors detect the correct label position

- A label is applied smoothly and precisely

- Optional coding printers add batch numbers or expiration dates

This seamless transition between the Automatic Filling Machine and Labeling Machine reduces manual labor, prevents errors, and increases throughput.

Labeling Techniques for Flexible Packaging

1. Top Labeling

This method places the label on the top of a pouch or sachet. It’s common for branding, logos, and instructions.

2. Wrap-Around Labeling

Used for tube-like flexible packs, the label wraps completely around the body. This is often seen in roll-on deodorants or gel packs.

3. Front-and-Back Labeling

Ideal for standing pouches that need two-sided information—branding on the front, and ingredients or instructions on the back.

Each of these techniques requires a different setup on the Labeling Machine. The right machine allows for quick switching between them, especially when your Automatic Filling Machine supports multiple products.

Top Features to Look For

To get the best results from your Labeling Machine, look for the following features:

- Conveyor Control: Smooth transport to reduce bag shaking

- Tension Adjusters: Prevent labels from lifting due to packaging movement

- Advanced Sensors: Detect labels and package edges precisely

- Hot Stamp or Inkjet Printer: Optional for adding date codes or serial numbers

- Quick Setup and Changeover: Essential when switching between product types

When your Labeling Machine and Automatic Filling Machine share smart controls or operate through the same PLC system, your production becomes even more efficient.

Challenges and Solutions

Challenge: Wrinkling and Peeling

Flexible packaging often causes label distortion. Choose a Labeling Machine that uses air blow, wipe-on, or tamp-blow systems to ensure clean application.

Challenge: Static Electricity

Plastic materials generate static, which can interfere with label placement. Anti-static brushes or ionizers integrated into the machine solve this problem.

Challenge: Misalignment During Filling

Products may expand or distort during filling. Syncing the Labeling Machine with the Automatic Filling Machine helps manage this by adjusting timing and spacing automatically.

Maintenance and Training

Even the best Labeling Machine needs regular care. Clean rollers, check sensors, and calibrate tension settings weekly. Do the same for your Automatic Filling Machine—keep nozzles clean and seals tight.

Training staff is also crucial. Operators should understand:

- How to adjust settings for different package types

- How to handle jams or misfeeds

- How to perform quick changeovers

- How to clean and store components properly

Proper training ensures uptime and consistent performance across shifts.

Final Thoughts

Flexible packaging is the future of smart, efficient product delivery. A well-designed Labeling Machine helps you take full advantage of this trend. It allows for fast, accurate, and attractive labeling that stays put, even on soft or oddly shaped surfaces.

When combined with a high-quality Automatic Filling Machine, your packaging process becomes a powerhouse of speed and consistency. Whether you’re in food, health, cosmetics, or cleaning products, this duo ensures your flexible packages are ready for the market.