Packaging in the cleaning industry requires not only speed and precision but also durability and chemical resistance. Labels must stay intact through transport, handling, and use. To meet these demands, companies rely on high-performance machinery—starting with a Labeling Machine and an Automatic Filling Machine. These two systems work together to improve efficiency and maintain product quality across a wide range of detergent and cleaning containers.

In this article, we will explore the best solutions for labeling detergent and cleaning products. We’ll also highlight how integrating a Labeling Machine with an Automatic Filling Machine creates a powerful, streamlined production line.

Why Labeling Is So Important for Cleaning Products

In the cleaning products market, the label carries more than just branding. It provides safety warnings, ingredients, dilution instructions, and usage guidelines. Therefore, the Labeling Machine must be accurate and capable of high-volume operation.

A poor label application can result in:

- Miscommunication of important safety data

- Legal compliance issues

- Damaged brand image

For these reasons, manufacturers must rely on a durable and precise Labeling Machine that works consistently even on slippery or oddly shaped bottles.

Containers Common in Detergent and Cleaning Product Packaging

Cleaning products come in a wide range of container types, including:

- Large gallon bottles

- Small hand soap bottles

- Spray bottles

- Squared jugs

- Pouches and refill packs

Each type poses a unique challenge. That’s why a versatile Labeling Machine must be adjustable to fit multiple shapes and sizes. The integration with an Automatic Filling Machine ensures that containers are properly filled and aligned before the labeling step begins.

How the Labeling Process Works

A professional Labeling Machine functions in sync with the rest of the production line. Here’s a typical sequence:

1. Filling Stage

An Automatic Filling Machine accurately dispenses liquid detergent, bleach, sanitizer, or disinfectant into containers. This system ensures each bottle is filled to the exact volume without overflow.

2. Capping Stage

After filling, containers are capped automatically to prevent spillage and prepare the container for labeling.

3. Labeling Stage

The containers then pass through the Labeling Machine, where high-adhesion labels are applied. Labels may include product names, barcodes, expiration dates, and hazard symbols.

4. Inspection and Ejection

A final sensor checks for label presence and position. If a label is missing or applied incorrectly, the bottle is removed from the line.

Features to Look for in a Labeling Machine for Detergents

Not every Labeling Machine is suitable for cleaning products. Here are the essential features to consider:

1. Chemical-Resistant Components

Cleaning products can leak or emit vapors. The Labeling Machine should be built with corrosion-resistant materials like stainless steel and chemically resistant rubber.

2. High-Tack Adhesive Support

Labels must remain secure despite exposure to moisture or chemicals. The Labeling Machine should accommodate labels with strong adhesives for long-lasting results.

3. Adjustable for Various Bottles

Your Labeling Machine should be able to handle everything from small bottles of dish soap to large containers of industrial disinfectant.

4. Speed and Precision

High-volume production requires a Labeling Machine that can operate fast while maintaining perfect accuracy.

5. Integration with an Automatic Filling Machine

The most efficient systems operate in a continuous flow. Your Labeling Machine should work seamlessly with the Automatic Filling Machine, ensuring clean bottles are labeled immediately after capping.

Benefits of Using a Labeling Machine in Cleaning Product Packaging

The advantages of using a professional-grade Labeling Machine are substantial:

1. Consistent Brand Appearance

A properly applied label increases shelf appeal. The Labeling Machine ensures every bottle looks clean, clear, and professional.

2. Compliance and Safety

Cleaning products are regulated. Labels must contain hazard symbols and usage guidelines. A dependable Labeling Machine applies these details in exactly the right location.

3. Increased Productivity

Manual labeling is slow and error-prone. An automated Labeling Machine can apply hundreds of labels per hour without fatigue or mistake.

4. Cost Efficiency

Automated systems reduce labor costs and eliminate waste due to misapplied or damaged labels. Over time, the Labeling Machine pays for itself.

Why Combine a Labeling Machine with an Automatic Filling Machine?

The perfect production line includes both an Automatic Filling Machine and a Labeling Machine. Here’s why they should work together:

- The filling machine ensures accurate liquid volume in every container.

- The labeling machine adds necessary product and safety information.

By combining both, your production line becomes more streamlined and efficient. You reduce downtime, avoid human error, and create a clean workflow that is both fast and reliable.

Types of Labeling Machines for Detergents

Different machines serve different container shapes. Here are some suitable types:

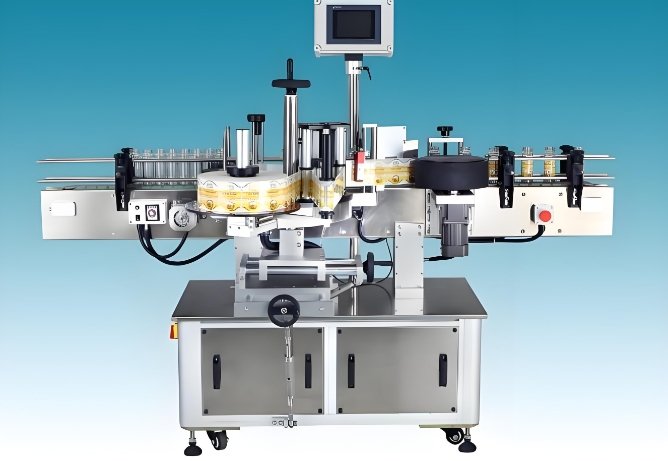

Wrap-Around Labeling Machine

For round bottles like window cleaner sprays or toilet bowl cleaners. The label wraps around the entire container.

Front-and-Back Labeling Machine

Ideal for larger jugs or square containers. This Labeling Machine applies a label to both the front and the back of each product.

Top-and-Bottom Labeling Machine

Some disinfectant wipes and powder detergents come in tubs. This machine applies labels to the lid and base.

Print-and-Apply Labeling Machine

These systems print barcodes or batch numbers in real time and apply them instantly. This is helpful for inventory tracking and regulatory compliance.

Applications Across the Cleaning Industry

These machines work with a wide range of products, including:

- Liquid detergents

- Powder laundry soaps

- Toilet cleaners

- Surface sanitizers

- Disinfectant sprays

- Bleach bottles

- Multi-purpose cleaners

Regardless of viscosity, bottle shape, or label size, the combination of an Automatic Filling Machine and a Labeling Machine provides the right solution.

Final Thoughts

When it comes to packaging detergent and cleaning products, accuracy and durability matter. A high-performance Labeling Machine ensures every label sticks perfectly and includes the correct information. Paired with an Automatic Filling Machine, the system delivers a consistent, fast, and hygienic packaging process.

Whether you’re bottling hand soap, window cleaner, or heavy-duty industrial degreasers, the right machinery makes all the difference. Invest in a reliable Labeling Machine, match it with a quality Automatic Filling Machine, and experience smooth, compliant, and professional packaging—every single time.