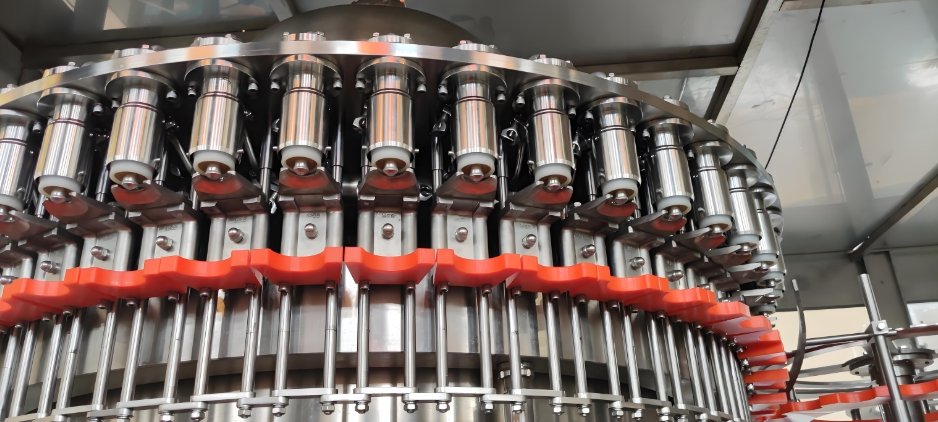

Running a business is expensive. Cutting costs is a priority. A Beverage Filling Machine helps achieve this. It reduces waste, saves time, and lowers labor costs. Adding an Automatic Filling Machine increases savings even more.

This article explains how these machines save money.

Efficiency Equals Savings

Efficiency is critical in production. A Beverage Filling Machine works faster than manual methods. It fills more containers in less time.

Benefits:

- Increased output.

- Reduced delays.

- Faster delivery.

Time saved equals money saved.

Reduced Labor Costs

Manual filling requires many workers. An Automatic Filling Machine eliminates the need for large teams. It handles filling, capping, and labeling.

Cost-Effective Labor:

- Fewer workers needed.

- Lower wages paid.

- Minimized human error.

Automation reduces payroll expenses significantly.

Minimized Waste

Waste costs money. A Beverage Filling Machine prevents overfills and spills. It measures liquids precisely.

How It Reduces Waste:

- Accurate filling levels.

- No product loss.

- Less cleanup needed.

Saving resources cuts overall costs.

Energy Efficiency

Energy bills are high. Modern Automatic Filling Machines consume less power. This lowers operational costs.

Energy-Saving Features:

- Low-energy motors.

- Power-saving modes.

- Efficient designs.

Energy-efficient machines reduce monthly expenses.

Durability and Longevity

Machines are a big investment. Durable Beverage Filling Machines last for years. They require fewer repairs and replacements.

Long-Term Savings:

- Less frequent maintenance.

- Reduced downtime.

- Reliable performance.

A durable machine saves money over its lifetime.

Faster Turnaround

Speed impacts profits. An Automatic Filling Machine completes tasks quickly. It reduces production cycles.

Financial Impact:

- More products delivered faster.

- Increased customer satisfaction.

- Higher sales revenue.

Quick production boosts income and reduces costs.

Multi-Functionality

A Beverage Filling Machine does more than fill. It integrates with capping and labeling systems. This reduces the need for extra equipment.

Combined Operations:

- Fewer machines to buy.

- Lower setup costs.

- Streamlined processes.

Multi-functional machines reduce initial investment and ongoing expenses.

Maintenance Costs

Old machines need constant repairs. New Beverage Filling Machines are low-maintenance.

Maintenance Savings:

- Self-cleaning features.

- Easy-to-replace parts.

- User-friendly designs.

Proper maintenance ensures fewer breakdowns.

Inventory Management

Overproduction leads to waste. A precise Automatic Filling Machine produces just what is needed.

Inventory Control:

- Avoids surplus.

- Reduces storage costs.

- Minimizes product loss.

Controlled production saves money.

Bulk Production

A Beverage Filling Machine handles bulk orders with ease. It reduces costs per unit.

Cost Advantages:

- Lower production costs.

- Increased profit margins.

- Fewer resources used.

Economies of scale make production cheaper.

Error Reduction

Errors waste time and resources. An Automatic Filling Machine ensures consistent results.

Accuracy Benefits:

- No overfills.

- No underfills.

- Perfect measurements every time.

Reducing errors saves significant money.

Adaptability

A Beverage Filling Machine works with different liquids and containers. This adaptability reduces the need for multiple machines.

Versatile Use:

- Handles juices, soda, and more.

- Fits various bottle sizes.

- Adjusts to production needs.

Versatility eliminates extra equipment costs.

Environmental Savings

Sustainable practices save money. A modern Automatic Filling Machine reduces waste and energy consumption.

Green Benefits:

- Lower disposal costs.

- Reduced power usage.

- Eco-friendly design.

Businesses save money and the environment simultaneously.

Choosing the Right Machine

Investing in the right Beverage Filling Machine matters. Picking the wrong one can lead to higher costs.

Selection Tips:

- Match machine capacity with production needs.

- Check energy efficiency.

- Look for easy maintenance features.

A good choice ensures long-term savings.

A Beverage Filling Machine saves costs in many ways. It reduces waste, saves time, and lowers labor expenses. Adding an Automatic Filling Machine increases efficiency even more.

Invest in a quality machine today. Watch your production costs drop and profits rise.