Bottling accuracy is crucial in wine production. Overfilling leads to waste, while underfilling affects product quality and compliance. A Wine Filling Machine ensures precision in every bottle. An Automatic Filling Machine further enhances accuracy by reducing human error and maintaining consistency.

This article explains how a Wine Filling Machine improves bottling accuracy and why it is essential for wineries.

1. The Importance of Accuracy in Wine Bottling

Accurate bottling affects:

- Product quality – Consistent fill levels ensure uniformity.

- Regulatory compliance – Laws require specific fill levels.

- Cost efficiency – Prevents wine loss and maximizes output.

- Brand reputation – Customers expect high-quality, precisely filled bottles.

A Wine Filling Machine ensures each bottle gets the correct amount of wine, preventing inconsistencies.

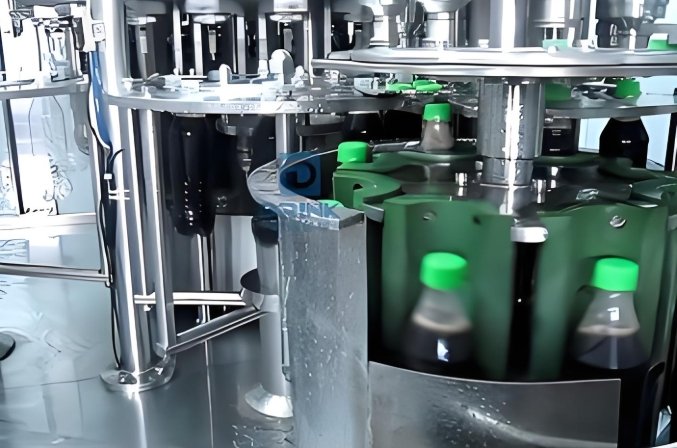

2. How a Wine Filling Machine Works

A Wine Filling Machine automates the bottling process. Here’s how it operates:

- Bottles move into position on a conveyor.

- Sensors detect bottle placement to ensure proper alignment.

- Filling nozzles dispense wine at controlled speeds.

- Liquid levels are monitored to prevent overfilling.

- Filled bottles move to the capping station for sealing.

An Automatic Filling Machine performs these steps quickly and accurately, reducing errors.

3. Key Features of a Wine Filling Machine for Accuracy

A Wine Filling Machine includes features that enhance accuracy:

1. Advanced Sensors

- Detects bottle position and size.

- Prevents filling errors due to misalignment.

2. Precision Nozzles

- Controls the flow of wine.

- Eliminates drips and overflows.

3. Automated Level Control

- Ensures uniform fill levels.

- Adjusts based on bottle volume.

4. Speed Control Mechanism

- Prevents splashing.

- Adapts to different wine viscosities.

An Automatic Filling Machine uses these features to improve accuracy in every bottle.

4. Types of Wine Filling Machines for High Accuracy

Different Wine Filling Machines offer various accuracy levels.

1. Gravity Wine Filling Machine

- Uses gravity to fill bottles.

- Best for still wines.

- Ensures steady, controlled flow.

2. Vacuum Wine Filling Machine

- Removes air before filling.

- Ideal for premium wines.

- Prevents oxidation and flavor loss.

3. Counter-Pressure Wine Filling Machine

- Designed for sparkling wines.

- Maintains carbonation.

- Prevents foaming and overflow.

4. Fully Automatic Filling Machine

- High-speed operation.

- Minimal human intervention.

- Ensures maximum accuracy.

Each Wine Filling Machine enhances accuracy in different ways, depending on winery needs.

5. Benefits of Using an Automatic Filling Machine for Accuracy

An Automatic Filling Machine provides wineries with several advantages:

1. Consistent Fill Levels

- Eliminates overfilling and underfilling.

- Ensures every bottle meets regulatory standards.

2. Faster Bottling Speed

- Handles large volumes efficiently.

- Reduces bottling time without compromising accuracy.

3. Minimal Waste

- Reduces spillage and overflow.

- Maximizes wine utilization.

4. Improved Hygiene

- Reduces human contact.

- Prevents contamination and maintains product integrity.

5. Lower Labor Costs

- Reduces reliance on manual labor.

- Ensures accuracy with minimal supervision.

A high-quality Wine Filling Machine helps wineries maintain precision while improving efficiency.

6. How to Choose the Best Wine Filling Machine for Accuracy

When selecting a Wine Filling Machine , consider the following factors:

1. Production Volume

- Small wineries: Semi-automatic models.

- Large wineries: High-speed Automatic Filling Machines .

2. Wine Type

- Still wines: Gravity-based Wine Filling Machine .

- Sparkling wines: Counter-pressure Automatic Filling Machine .

3. Bottle Size Flexibility

A good Wine Filling Machine adjusts to different bottle sizes.

4. Cleaning and Maintenance

Choose an Automatic Filling Machine with self-cleaning features for easy maintenance.

5. Cost vs. Long-Term Savings

Investing in an Automatic Filling Machine saves money by reducing waste and labor costs.

7. Maintaining a Wine Filling Machine for Long-Term Accuracy

Regular maintenance ensures a Wine Filling Machine operates efficiently. Follow these steps:

1. Clean Regularly

- Prevents residue buildup.

- Ensures consistent fill accuracy.

2. Inspect for Leaks

- Check hoses and seals.

- Fix leaks immediately to prevent wine loss.

3. Lubricate Moving Parts

- Reduces friction.

- Ensures smooth operation.

4. Monitor and Calibrate Sensors

- Ensures precise fill levels.

- Prevents underfilling or overfilling.

Proper maintenance keeps an Automatic Filling Machine in peak condition.

8. Manual vs. Automatic Wine Filling Machines: Accuracy Comparison

| Feature | Manual Filling | Automatic Filling Machine |

|---|---|---|

| Speed | Slow | Fast |

| Accuracy | Inconsistent | Precise |

| Waste | High | Low |

| Labor Costs | Expensive | Reduced |

| Hygiene | Moderate | High |

An Automatic Filling Machine is the best choice for wineries prioritizing accuracy.

9. Why Wineries Are Investing in Automatic Wine Filling Machines

Modern wineries prefer Automatic Filling Machines for these reasons:

- Higher production capacity – Fills thousands of bottles accurately.

- More precise fills – Reduces wine loss.

- Better hygiene standards – Minimizes contamination risks.

- Lower operational costs – Saves money on labor.

- Seamless production process – Works with capping and labeling machines.

An Automatic Filling Machine ensures maximum efficiency while maintaining accuracy.

A Wine Filling Machine is essential for accurate bottling. It ensures precise fill levels, reduces waste, and improves efficiency. An Automatic Filling Machine further enhances accuracy by automating the process and minimizing errors.

Investing in a Wine Filling Machine helps wineries maintain product consistency, reduce costs, and improve overall quality. With the right machine, wineries can streamline production and achieve perfect bottling accuracy.