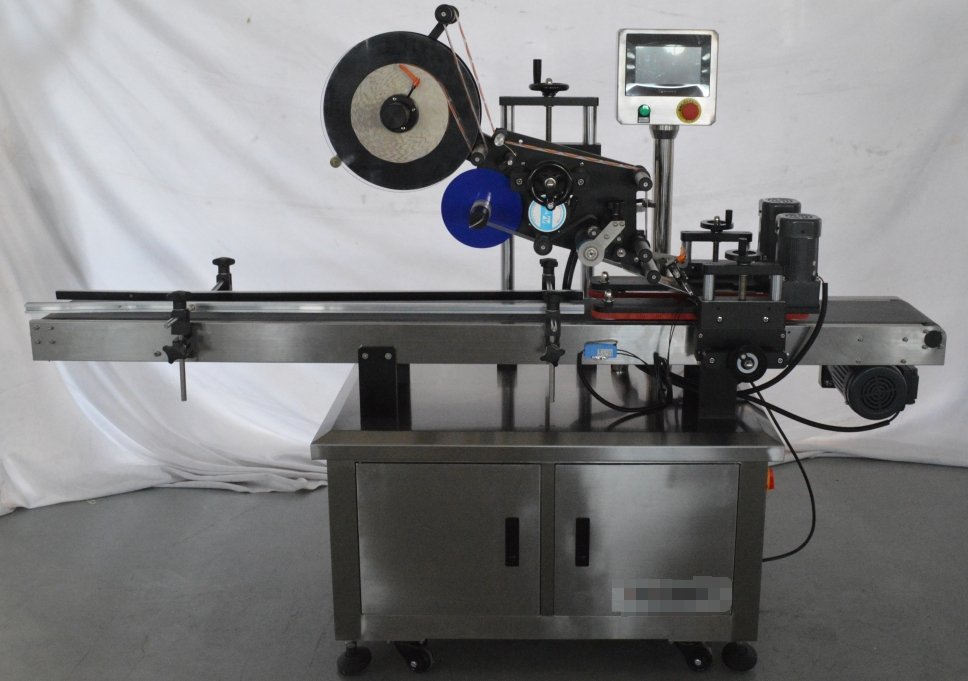

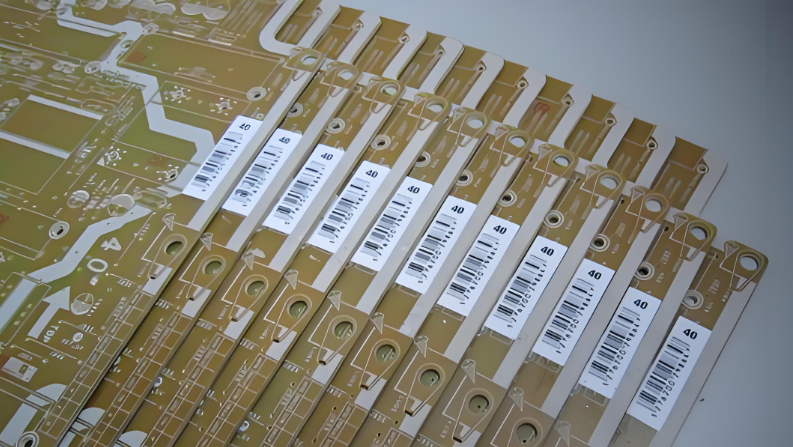

Labeling Machine for Top and Bottom Labels

Labeling Machine is a key tool for many industries. It helps businesses fill liquids, powders, or granules into containers. These machines are designed to improve efficiency. They also help reduce waste and errors.

Features of the Labeling Machines

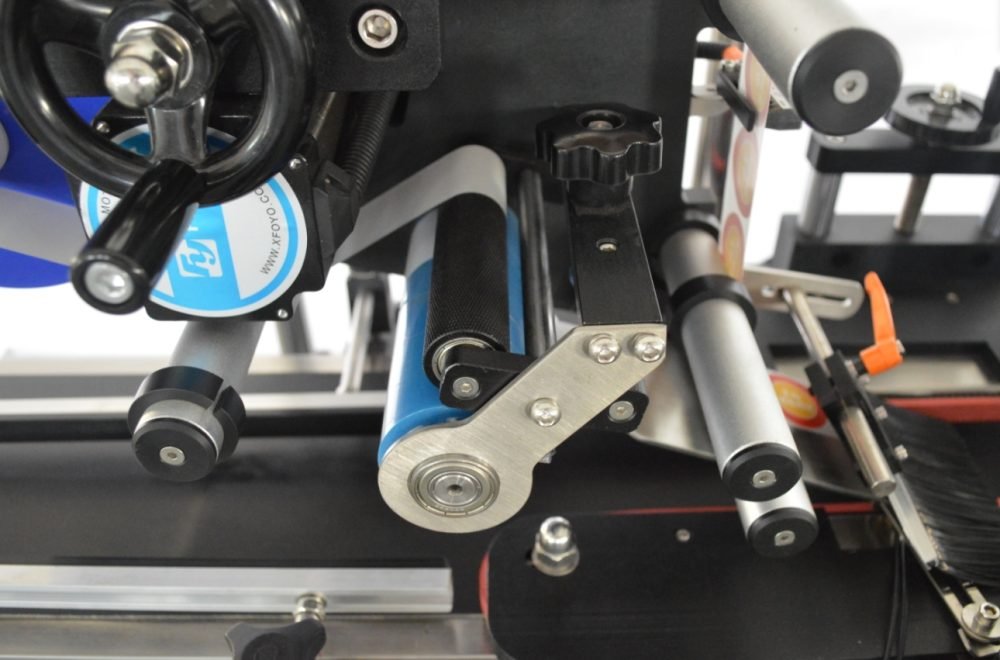

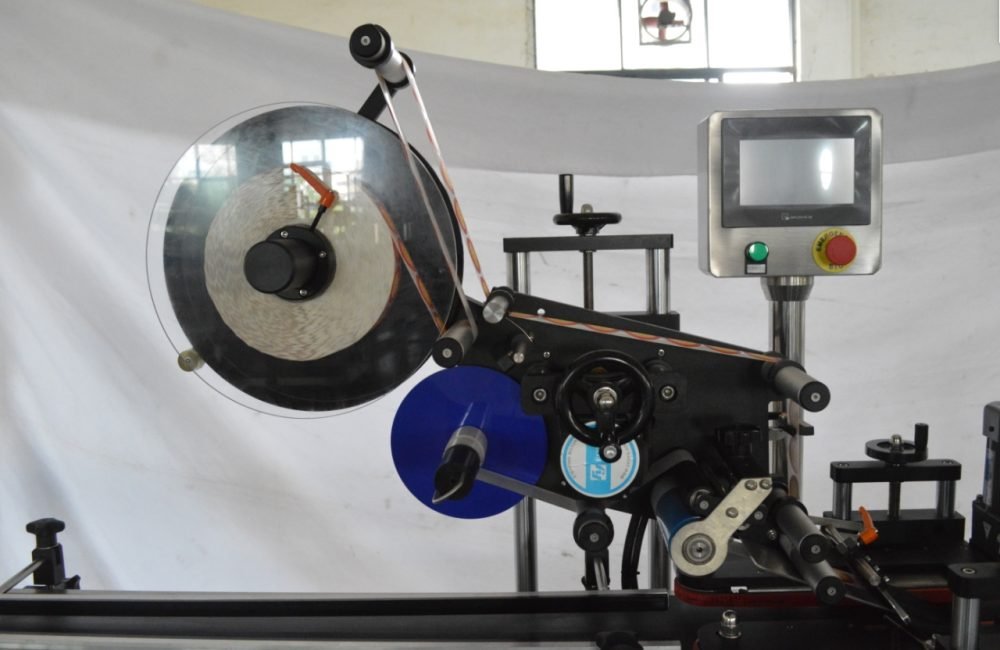

Supports Different Label Types: The flat labeling machines can apply paper labels, plastic labels, and custom materials, allowing versatility for various products.

Adjustable for Multiple Shapes & Sizes: It adapts to different containers boxes, jars, bottles, pouches making it suitable for diverse packaging needs.

Flexible Speed Control: Users can set different labeling speeds to match production requirements, improving efficiency and workflow.

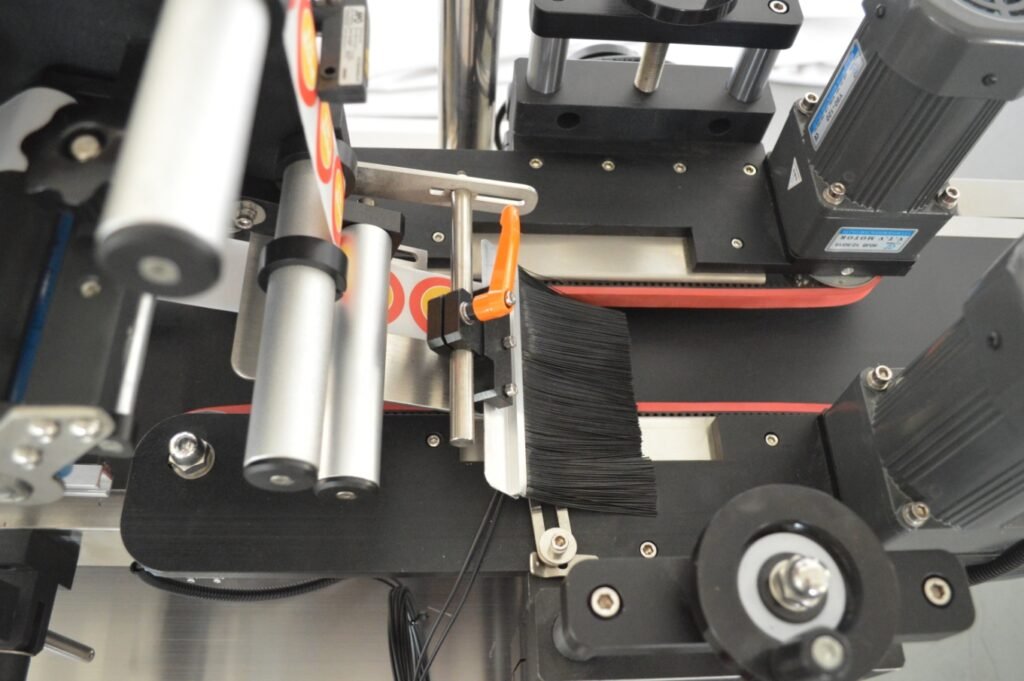

High Versatility: The machine handles flat surfaces with precision, ensuring smooth, wrinkle-free labeling for a clean and professional look.

Applications of the Flat Labeling Machines

Food Industry: Used for labeling jars, bottles, boxes, and packaged foods. Clear labels help display branding, nutritional facts, and product information.

Cosmetic Industry: Applies labels to bottles of lotion, creams, serums, and skincare products, enhancing product presentation and customer identification.

Pharmaceutical Industry: Ensures accurate label placement on medicine containers, providing crucial details like dosage, batch number, and safety instructions.

Chemical Industry: Labels containers of oils, cleaners, and household chemicals. Clear labeling helps with safety, compliance, and product handling.

Benefits of Using a Flat Labeling Machines

Using flat labeling machines has many benefits. It increases production speed. Businesses can label more products in less time. This leads to higher efficiency. The machine reduces the chances of errors. Labels are applied consistently. This improves the overall quality of products.

The flat labeling machinesis easy to operate. Users can learn how to use it quickly. The control panel is user-friendly. Adjustments can be made without any hassle. Maintenance is also simple. Regular cleaning keeps the machine running smoothly.

Why Choose a Flat Labeling Machine?

A flat labeling machine represents a smart investment for any business. Specifically, it saves significant time and increases total output. The operator can easily integrate the machine into existing production lines. Consequently, this setup enhances operations without requiring a complete overhaul.

Moreover, the equipment remains highly cost-effective. Accordingly, businesses save on labor costs because the system automates a previously manual task. Manual labeling often proves slow and error-prone; however, the flat labeling machine solves these issues effectively. It provides quick, reliable labeling for every unit. Therefore, this technology ensures that your products reach the market with consistent, professional branding. Ultimately, choosing the right labeling solution streamlines your entire packaging workflow and secures a better return on investment.

In conclusion, a flat labeling machine is vital for modern production. It applies labels to the top and bottom of products efficiently. With its many applications, it benefits various industries. From food to pharmaceuticals, this machine ensures accuracy and speed. Investing in a labeling machine improves productivity and quality.