Powder Filling Machine Applications and Bottle Shapes

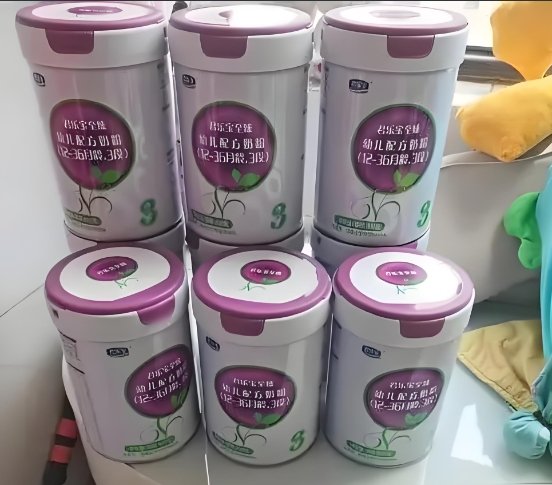

A powder filling machine is widely used in industries where accurate filling of powders into bottles or containers is required. This machine can fill a range of powdery substances, from fine dust-like powders to granular products. The powder filling machine is essential in industries like pharmaceuticals, food production, and cosmetics, where precise filling is necessary to ensure product consistency and efficiency.

Applications for the Powder Filling Machine

The powder filling machine is designed for a variety of products, particularly in industries that require the packaging of dry goods. It can handle powders like flour, protein powders, pharmaceutical powders, spices, and even cosmetic products like loose face powders. Its versatility makes it a key piece of equipment for many companies.

In addition to dry powders, the powder filling machine is sometimes adaptable to handle certain types of liquid-like products that have granular or powdery consistencies. These are often found in the food industry where a product might be a thick powder or have a granular, semi-liquid texture, such as some nutritional supplements or thick pastes that flow like powder.

Shape of Bottles

One of the biggest advantages of a powder filling machine is its ability to work with various bottle shapes and sizes. The machine can fill small, narrow-necked containers as well as large, wide-mouthed jars. In the pharmaceutical industry, small vials are commonly used to package powders, while larger containers might be used in the food or cosmetic industries.

For different bottle shapes, the powder filling machine uses adjustable mechanisms to ensure the powder flows correctly into each container without spilling. The machine’s adaptability helps manufacturers fill powders into round, square, or irregularly shaped bottles with ease. This feature makes the powder filling machine suitable for companies that package their products in unique or custom-shaped containers.

How the Machine Measures Powder

Accurate measurement is one of the most important functions of a powder filling machine. Precision ensures product consistency and prevents issues such as underfilling or product waste.

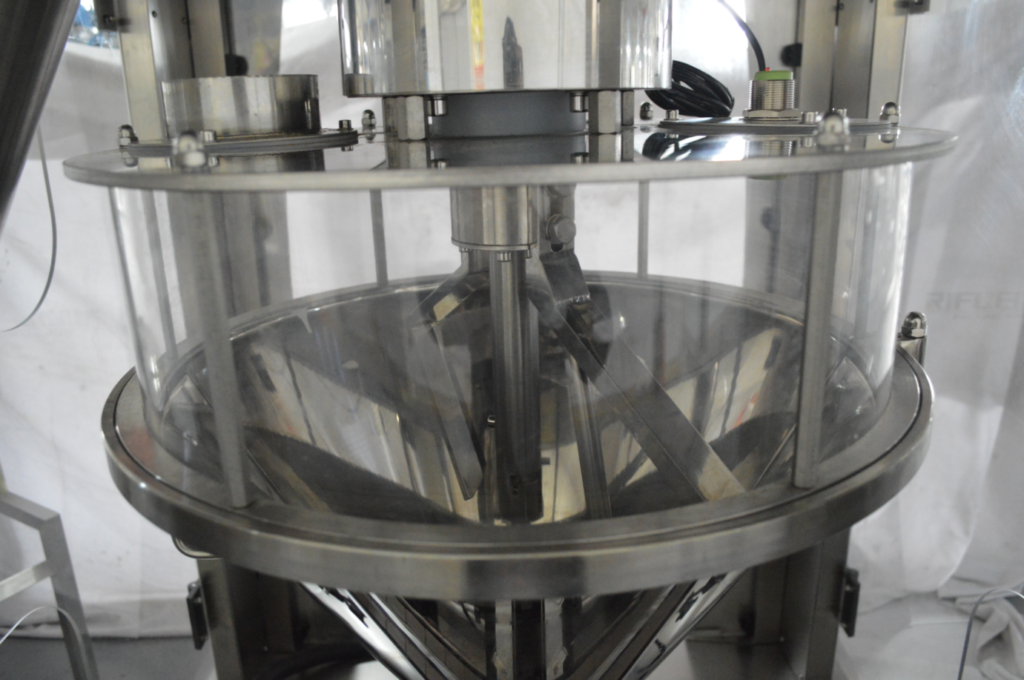

The most widely used measuring method is the auger-based system. In this system, an auger screw transports powder from the hopper into the container. The amount of powder dispensed depends on the number of auger rotations. Sensors and a digital control system monitor each rotation to ensure the correct volume is delivered every time.

The auger system can be fine-tuned to match different product characteristics and container sizes. For industries that require extremely high accuracy, such as pharmaceuticals, the machine may include integrated weighing systems. These systems check the weight of each filled bottle. If an error is detected, the machine automatically adjusts the next fill or rejects the underfilled container for reprocessing.

Some powder filling machines use volumetric cups or piston-based measurement. In these methods, the powder is dispensed into pre-measured compartments, which are then emptied into each bottle. This method is ideal for faster filling processes where precision requirements are slightly lower.

A powder filling machine is essential for industries that require accurate and efficient powder packaging. Its ability to work with different bottle shapes and sizes, combined with precise measuring technology, ensures consistent, high-quality results. Whether filling small vials for pharmaceuticals or larger containers for food products, the machine helps manufacturers meet production demands while maintaining strict product standards.