Wine Filling and Sealing Machines for Glass Bottles: A Complete Solution

In the wine industry, high-speed and precise bottling processes are crucial. A wine filling machine, combined with a bottle washing machine and a cap sealing machine, offers a complete solution for glass bottles. These machines work together to wash, fill, and seal bottles efficiently, ensuring product quality while speeding up production.

Applications of Wine Filling Machines

Additionally, a wine filling machine accurately dispenses wine into glass bottles at high speeds. It reduces product waste and ensures consistent fill levels. However, wine is sensitive to air exposure, which can spoil the product.As a result, many wine filling machines use vacuum systems or nitrogen purging to remove air from bottles before sealing. This helps maintain the wine’s freshness and flavor.

Moreover, modern wine filling machines are automated and adaptable, handling various bottle sizes and types.This makes them ideal for wineries producing different wine varieties, as the system can easily be adjusted for different production needs.

The Role of the Bottle Washing Machine

Moreover, Clean bottles are critical for maintaining wine quality. A bottle washing machine removes dust, dirt, and contaminants from glass bottles before filling. Using water, air, or cleaning solutions, the machine thoroughly cleans the inside and outside of the bottles. For added protection, many systems also sterilize bottles using hot water or steam.

These machines are designed for speed, handling large volumes of bottles quickly. This ensures a steady supply of clean bottles for the wine filling machine, keeping production lines running smoothly.

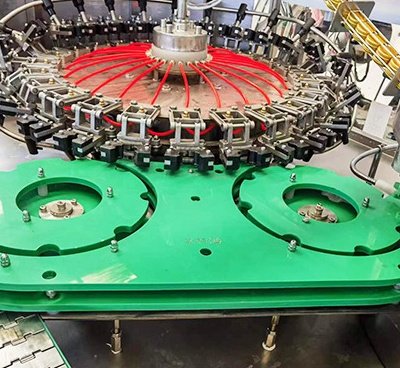

Cap Sealing Machine for Glass Bottles

For example, After filling, bottles need to be securely sealed. A cap sealing machine applies corks, screw caps, or metal closures to the bottles. Sealing immediately after filling prevents leaks and contamination, preserving the wine’s quality.

Cap sealing machines work in sync with the wine filling machine, automatically capping bottles right after they’re filled. Many machines also use sensors to ensure caps are properly placed, providing an extra layer of quality control.

High-Speed Integrated Systems

Furthermore, Combining a wine filling machine, bottle washing machine, and cap sealing machine into one integrated system increases efficiency. These high-speed systems can process thousands of bottles per hour, making them perfect for large-scale wineries. The automation reduces manual labor, minimizes human error, and ensures consistency across all bottles.

Benefits of Integrated Wine Bottling Systems

- Increased Efficiency: Additionally, automated systems allow for faster production, reducing downtime and increasing output.

- Consistent Quality: Machines ensure precise filling, sealing, and cleanliness, which helps maintain wine quality in line with wine production.

- Reduced Labor Costs: Automation lowers the need for manual labor, resulting in cost savings.

- Flexibility: The ability to handle different bottle sizes and cap types makes these systems adaptable for various wine products.