Automatic Milk Powder Filling Machine for Cans: A Comprehensive Guide

An automatic milk powder filling machine is crucial for efficiently filling milk powder into cans with precision and speed. This type of machine is widely used in the dairy industry to ensure accurate packaging, prevent contamination, and maintain product quality. The system’s integration with filling, sealing, and quality control processes makes it essential for manufacturers who need to meet large-scale production demands.

Applications of Automatic Milk Powder Filling Machines

The primary application of an automatic milk powder filling machine is to fill dry, powdered milk into cans. Manufacturers widely use this machine in the food and beverage industry. especially for infant formula, nutritional supplements, and other dairy-based products.

The powder filling machine system ensures precise weight control to avoid overfilling or underfilling, helping manufacturers reduce waste and improve profit margins.

Additionally, beyond dairy products, this machine can also be used in other industries. Pharmaceutical and chemical companies rely on powder filling machines to package powdered substances into cans safely and efficiently.

Therefore, its versatility makes the automatic milk powder filling machine a valuable tool for any business handling powder-based products.

How the Filling Process Works

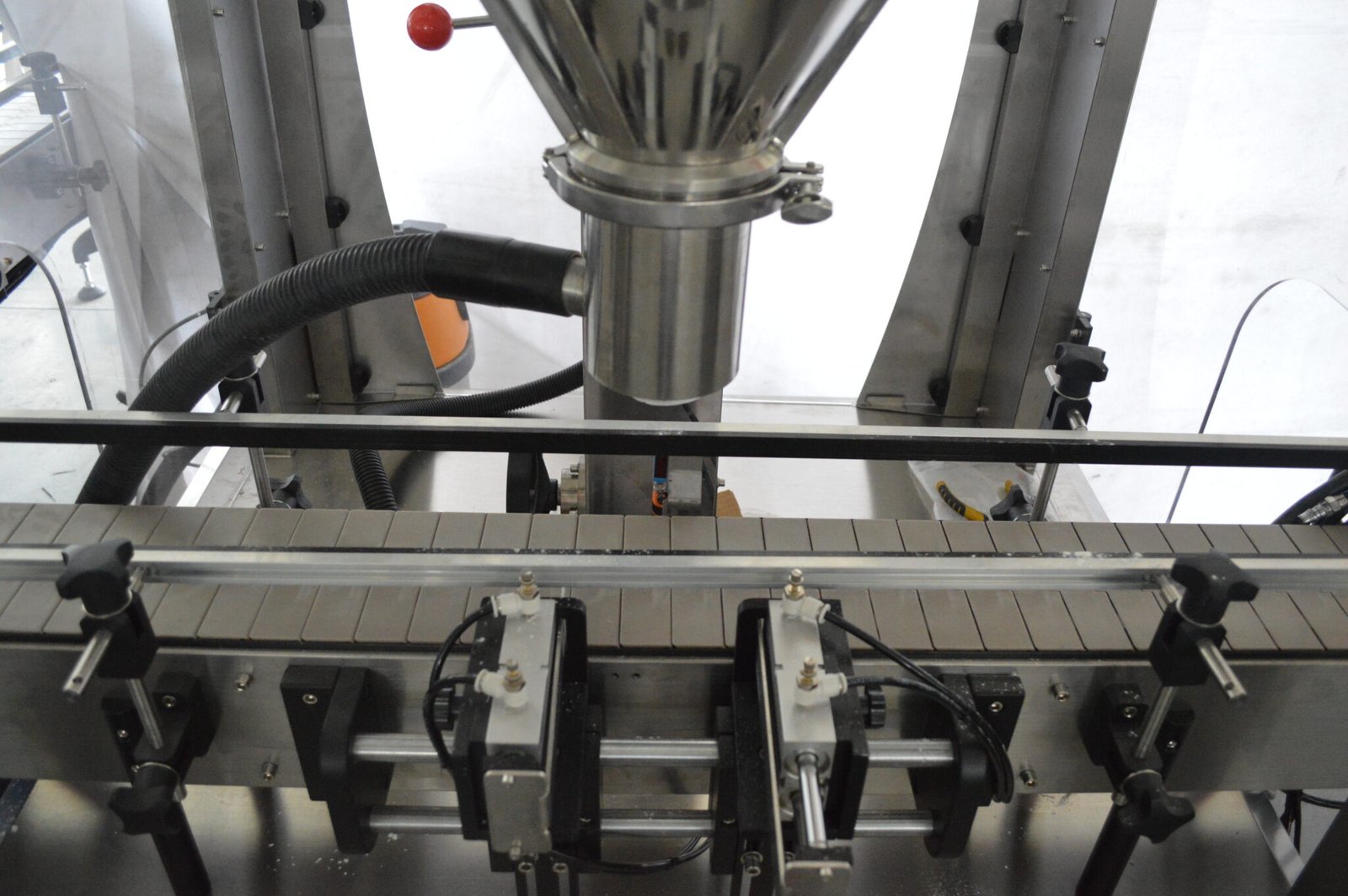

The automatic milk powder filling machine typically uses an auger filler, which dispenses powder into cans with exceptional precision. The machine first positions the empty cans under the filling nozzles.

Once aligned, the auger rotates and dispenses a pre-determined amount of powder into each can. This automated process ensures consistent filling across the entire production line.

Many modern filling machines also include nitrogen purging before sealing. This step removes oxygen from the cans, keeping the milk powder fresh and extending its shelf life. For products like infant formula, maintaining powder integrity is essential for consumer safety.

Cap Sealing Machine for Cans

After the filling process,This will drop passive voice below 10%. A cap sealing machine ensures that each can is securely sealed, preventing moisture or air from entering, which can spoil the milk powder.

Cap sealing machines can handle various types of closures, including metal lids and plastic seals, depending on the manufacturer’s specifications, in line with safety standards.

As a result, the sealing machine works together with the filling machine, automatically sealing each can right after filling. This seamless integration increases production speed and maintains product quality.

Benefits of an Automatic Milk Powder Filling Machine

Improved Efficiency: Automating the filling process allows manufacturers to increase production speed, achieving higher output with less manual labor.

Precision and Consistency: The auger filler ensures accurate powder measurements in every can, reducing waste and ensuring consistent product q