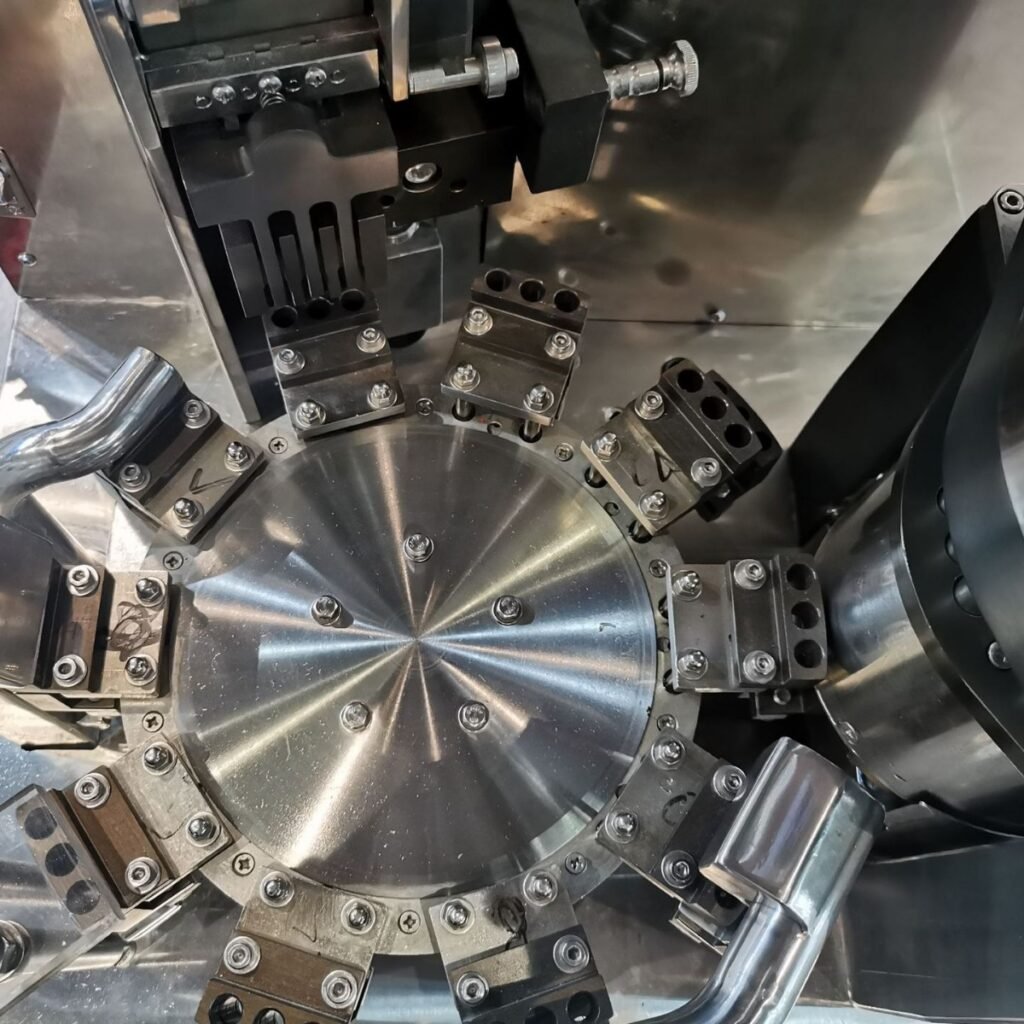

Medical Capsule Filling Machine

A medical capsule filling machine is essential in the pharmaceutical industry. It fills empty capsules with medicine. The process is quick, precise, and safe. In this article, we will explain how a capsule filling machine works and its benefits.

How a Capsule Filling Machine Works

The capsule filling machines uses advanced technology and can handle both powder and liquid medicines.

First, the machine separates the empty capsules into two parts: the capsule body and the cap. The capsule body is directed to the filling station.

At the filling station, the machine fills the capsule with medicine. Sensors ensure the correct amount is filled, preventing mistakes and ensuring accuracy.

Once filled, the machine transfers the capsule to the sealing station, where the cap is securely placed back onto the body.

Sealing Process

At the sealing station, the machine actively closes the capsule. The system places the cap securely onto the capsule body, ensuring the medicine stays inside and preventing contamination. As a result, the product remains safe and consistent.

After sealing, the capsules move directly to the packaging stage. Because the system operates automatically, it reduces the need for manual labor and significantly improves overall efficiency.

Applications of the Capsule Filling Machine

Capsule filling machines serve many industries. Most commonly, pharmaceutical companies, hospitals, and research laboratories rely on them for precise production.

In addition, these machines fill capsules with many types of medicines. For example, common applications include vitamins, antibiotics, and pain relievers.

Moreover, manufacturers widely use capsule filling machines for dietary supplements. In the health and wellness industry, companies frequently fill capsules with herbs and supplements. As a result, the process becomes faster, cleaner, and more accurate.

Benefits of Using a Capsule Filling Machine

There are many benefits to using a capsule filling machines. First, it saves time by filling hundreds of capsules per minute, which greatly increases productivity.

Second, it improves accuracy. The machine delivers the exact amount of medicine into each capsule, which helps prevent errors and reduce waste.

Additionally, the machine enhances safety. It lowers the risk of contamination by operating in a controlled and clean environment. This advantage is especially important in the pharmaceutical industry.

Finally, the machine seals capsules tightly, which helps keep the medicine fresh and effective for a longer period.

Versatility of the Capsule Filling Machines

Capsule filling machines offer excellent versatility and efficiency. They support capsules of different sizes and work with various types of medicines.

Furthermore, these machines handle powders, liquids, and semi-solid materials. Because of this flexibility, they meet a wide range of pharmaceutical production needs.

Why It Matters

The pharmaceutical industry demands precision. Medicines must be delivered in exact doses, and the capsule filling machine consistently ensures accurate results.

Without automation, manual filling often causes errors and inconsistencies. By using automated systems, manufacturers improve quality control and ensure every capsule contains the correct amount of medicine.

Learn more about capsule filling machines.