Introduction: Why Liquid Filling Machines Matter in 2025

A liquid filling machine is now essential for small and medium-sized businesses looking to streamline production, improve accuracy, and reduce manual labor. From cosmetics to sauces and beverages, automation has become the foundation of efficient liquid packaging.

Modern automatic filling machines are designed to meet diverse needs providing consistent results, scalability, and low maintenance. According to Packaging World, SMEs adopting automation experience up to 35% improvement in output efficiency.

If you are expanding your business in 2025, here are the top 10 liquid filling machines that combine affordability, reliability, and professional-grade performance.

1. Bottle Filling Machine – Reliable and Efficient Choice

A bottle filling machine is the most versatile option for small beverage and chemical producers. It handles both glass and plastic containers with exceptional accuracy.

This automatic filling machine uses flow meters and servo-driven controls to ensure uniform fill levels, reducing waste. Integrated with capping machines and labeling machines, it forms a complete packaging solution for SMEs.

2. Desk-Top Liquid Filling Machine – Compact Powerhouse

The desk-top filling machine is perfect for startups and small workshops with limited space. Despite its small size, it offers automated accuracy and fast changeovers between products.

Ideal for essential oils, syrups, or hand sanitizers, this model gives small producers the automation edge without high investment.

3. Gravity Liquid Filling Machine – Ideal for Low-Viscosity Products

Gravity-based liquid filling machines are simple yet powerful for filling thin liquids like water, juice, or vinegar. These machines rely on gravity flow to ensure consistent fill volumes.

Because of their low maintenance and cost-effectiveness, they are popular in food and beverage industries looking for a durable, entry-level automatic filling machine solution.

4. Piston Liquid Filling Machine – High Precision for Viscous Products

The piston liquid filling machine is ideal for thicker substances such as creams, sauces, or shampoos. Using pneumatic pistons, it ensures every container receives the exact amount of product.

When paired with the sauce filling machine, it becomes a high-performance solution for food manufacturers who require accuracy and smooth operation.

5. Overflow Liquid Filling Machine – Perfect for Aesthetic Bottling

Overflow fillers are designed to maintain uniform liquid levels across transparent bottles, creating a professional shelf appearance. This automatic filling machine is commonly used for cosmetics, cleaners, and beverages.

Its non-contact filling mechanism minimizes foam, ensuring clarity and consistency, especially for carbonated or sensitive liquids.

6. Volumetric Liquid Filling Machine – Accuracy and Flexibility

The volumetric liquid filling machine uses a metering system that dispenses a precise quantity of liquid into each bottle. It’s a favorite among small chemical and personal-care manufacturers.

This automatic filling machine integrates smoothly with wrapping packaging machines for a complete automation setup that enhances productivity.

7. Semi-Automatic Liquid Filling Machine – Affordable Transition to Automation

For businesses transitioning from manual to automated systems, the semi-automatic model is an excellent bridge. It reduces labor while maintaining control over each filling cycle.

This cost-effective liquid filling machine is suitable for startups that aim to upgrade later to a fully automatic filling machine as their production scales.

8. Wine and Beverage Filling Machine – Precision for Drinks Industry

The wine filling machine is specifically designed for beverages that require oxygen control and precise volume accuracy.

Its automated sealing and nitrogen flushing preserve product freshness. Beverage producers often pair it with carton packaging machines for an end-to-end production line.

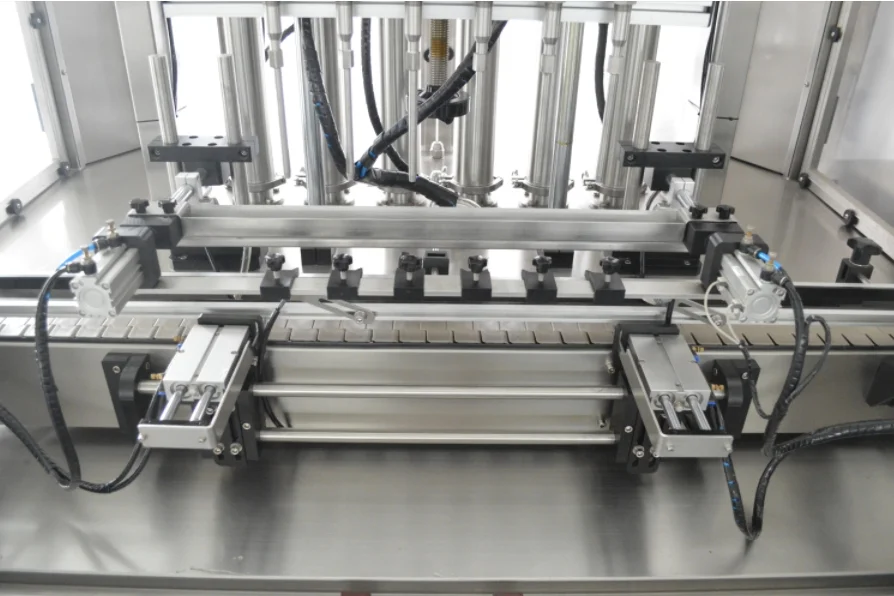

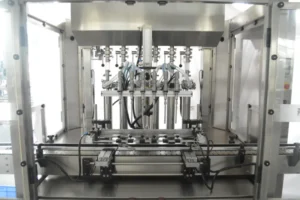

9. Multi-Head Liquid Filling Machine – Speed and Scalability

When demand grows, a multi-head automatic filling machine ensures fast and consistent output. Each nozzle operates independently, maintaining equal flow and fill weight.

According to Automation, multi-head systems can boost output by over 50% while maintaining tight control over product consistency.

10. Servo-Driven Automatic Filling Machine – Smart Technology for 2025

The latest generation of servo-driven automatic filling machines combines precision engineering with digital control. Using AI-driven sensors, they adapt to different container sizes and viscosities automatically.

They are ideal for industries needing flexibility, like pharmaceuticals and personal care. Similar technology powers the capsule filling machine, where fill accuracy is mission-critical.

How to Choose the Right Liquid Filling Machine?

When selecting an automatic filling machine, consider:

- Product Type: Is it liquid, semi-liquid, or viscous?

- Production Volume: Choose single-head for small batches or multi-head for higher capacity.

- Container Size: Adjustable nozzles handle diverse packaging formats.

- Budget & Scalability: Start with a desk-top filling machine and upgrade as your business grows.

Small and medium manufacturers can also integrate automation with labeling machines and palletizing packaging machines for a seamless workflow.

Benefits of Liquid Filling Automation

Investing in a liquid filling machine brings multiple advantages:

- Improved Accuracy: Each fill is digitally measured, eliminating product loss.

- Time Efficiency: Machines operate continuously with minimal supervision.

- Consistency: Perfect fill level for every bottle enhances brand image.

- Reduced Labor: Low manpower needs make it ideal for SMEs.

- Regulatory Compliance: Stainless-steel construction ensures hygiene and FDA compatibility.

As Pharmaceutical Processing World reports, automation in filling operations can reduce contamination risk by 80%, improving both safety and product quality.

Why Small Businesses Should Upgrade in 2025

The year 2025 is a turning point for small and medium manufacturers. With rising labor costs and customer expectations for consistency, adopting an automatic filling machine is no longer optional it’s a competitive necessity.

Companies that invest now can expand faster, handle larger orders, and improve profitability. From liquid to powder filling machines, automation supports scalability while maintaining precision.

Visit fillingmachinepp.com to explore a full range of advanced filling machines, labeling systems, and packaging solutions designed for every production scale.

Conclusion: Simplify Production with Smart Filling Machines

Whether you’re bottling juices, oils, or creams, a liquid filling machine ensures consistency, speed, and professional presentation. The top 10 options above give small and medium-sized businesses flexible automation for any product line.

Discover more about automation technology, production tips, and product comparisons on our Blogs page, or get expert advice through our Service Page to choose the best automatic filling machine for your business.

FAQs

1. Which liquid filling machine is best for small businesses?

The desk-top filling machine is ideal for small operations due to its compact design, easy maintenance, and cost efficiency.

2. What factors affect the choice of a liquid filling machine?

Product viscosity, production volume, and container type all influence the selection of your automatic filling machine.

3. Can I upgrade from semi-automatic to fully automatic?

Yes, most systems are modular, allowing small businesses to expand capacity over time.

4. How accurate are liquid filling machines?

Modern models achieve ±1% accuracy using servo motors and advanced sensors for consistent fill levels.

5. Where can I find affordable liquid filling machines?

Explore durable and affordable solutions at fillingmachinepp.com for complete automation packages.