In today’s competitive packaging world, precision, speed, and flexibility are non-negotiable. Industries need equipment that can do more in less time—without compromising on quality. A Labeling Machine with a multi-label application feature is a smart investment for any company looking to enhance product presentation and streamline operations. When paired with an Automatic Filling Machine, the combination delivers unmatched efficiency on the production floor.

This article explores the benefits, working principle, and industry applications of a Labeling Machine that can apply multiple labels on a single product, and how it pairs perfectly with an Automatic Filling Machine for complete automation.

What is a Multi-Label Application Feature?

The multi-label application feature in a Labeling Machine allows for the application of more than one label on a product during a single run. These labels may include:

- Front and back labels

- Top and bottom labels

- Wrap-around labels with additional side labels

- Promotional labels or tamper-evident seals

This feature is crucial for products that require detailed branding, regulatory compliance, or promotional information. It simplifies operations by reducing the need for multiple passes through different labeling systems.

How Does a Multi-Label Labeling Machine Work?

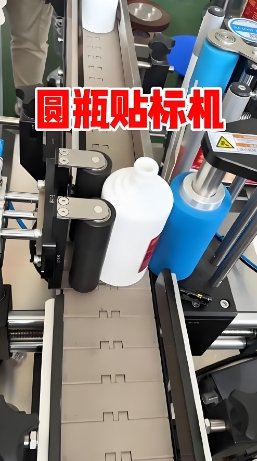

A Labeling Machine with a multi-label application feature uses multiple applicators, sensors, and positioning systems to place labels on several surfaces of a container. Bottles or containers are guided through the machine where sensors detect the orientation and trigger the appropriate applicator arms. Each label roll is loaded onto its designated station and synchronized to apply the label precisely on cue.

This system works in seamless coordination with an Automatic Filling Machine, which handles the accurate filling of containers before they reach the labeling station. The integration of these two systems creates a fully automated and uninterrupted packaging flow.

Advantages of Using a Multi-Label Labeling Machine

1. Enhanced Product Presentation

With the ability to apply multiple labels, you can showcase your brand on the front, provide legal information on the back, and offer a promotional label—all in one go. The Labeling Machine ensures these labels are aligned perfectly.

2. Improved Efficiency

The machine reduces downtime and eliminates the need for multiple labeling setups. Combined with an Automatic Filling Machine, your entire production line operates faster and more efficiently.

3. High Accuracy

Multiple sensors and servo motors ensure precise label placement, which is essential for meeting packaging standards and consumer expectations.

4. Versatility Across Products

This type of Labeling Machine is compatible with various product types and shapes—jars, bottles, tubes, pouches, and more. Whether you’re in food, pharma, or cosmetics, it delivers consistent results.

5. Cost Savings

Running multiple labeling operations separately increases labor and equipment costs. A multi-label Labeling Machine, when coupled with an Automatic Filling Machine, reduces labor dependency and operational costs.

Seamless Integration with an Automatic Filling Machine

The Automatic Filling Machine is an indispensable part of the production process. It fills each container with the precise amount of product—be it liquid, powder, or paste. Once the containers are filled and capped, they move directly to the Labeling Machine for multi-label application.

This integration creates a smooth, automated pipeline that minimizes human intervention and boosts production speed. You no longer need separate setups for filling and labeling. This synergy enhances line efficiency, especially for high-volume operations.

Applications Across Industries

Food and Beverage Industry

Bottles of juice, sauces, condiments, or nutritional drinks often require front and back labels. A Labeling Machine with multi-label application handles this easily, while the Automatic Filling Machine ensures precise volume control.

Pharmaceuticals

Medicines and supplements often have multiple labels for dosage instructions, batch numbers, and legal information. This makes the multi-label feature invaluable.

Cosmetics and Personal Care

Shampoos, lotions, and creams come in stylish bottles that demand flawless labeling. With this advanced Labeling Machine, companies can label front, back, and even apply decorative labels or security seals.

Chemicals and Detergents

Industrial and household cleaning products typically require detailed hazard information on labels. The multi-label system ensures compliance without compromising appearance.

Key Features to Look For

When choosing a Labeling Machine with a multi-label feature, consider the following:

- Touchscreen Interface: Enables easy setup and recipe recall

- Multiple Label Heads: Each with independent motor and control

- Bottle Orientation Systems: Ensures accurate label alignment

- Modular Design: For future upgrades or label configurations

- Compatibility: Should sync with your existing Automatic Filling Machine

Customization Options

Many manufacturers offer custom configurations to meet specific industry needs. Whether it’s dual-head application, wrap-around with side labeling, or tamper-evident tape placement, the Labeling Machine can be tailored to fit your exact requirements.

Custom solutions are especially useful when working with unique bottle designs or strict regulatory environments. These machines are flexible enough to label fragile glass vials or sturdy industrial jugs with equal precision.

Maintenance and Reliability

Routine maintenance is crucial to ensure that your Labeling Machine and Automatic Filling Machine continue performing at peak efficiency. Regular cleaning of sensors, checking for label roll tension, and lubricating moving parts can significantly extend machine life.

Also, having operator training and clear machine manuals reduces error rates and ensures consistent output.

Final Thoughts

A Labeling Machine with a multi-label application feature brings tremendous value to any modern production line. It adds speed, flexibility, and precision—all critical for today’s packaging demands. When paired with an Automatic Filling Machine, you get a robust and reliable system that streamlines the entire packaging process from start to finish.

Whether you’re labeling food jars, pharmaceutical bottles, or beauty products, this powerful combination will help your brand stand out—while keeping your operations cost-effective and compliant.