The packaging industry is evolving. A Tube Filling and Sealing Machine must keep up. New technology improves speed, accuracy, and efficiency.

An Automatic Filling Machine ensures high-quality production. It reduces waste and increases output.

Let’s explore the latest innovations for 2025.

1. Faster Tube Filling and Sealing

A Tube Filling and Sealing Machine now operates at higher speeds. It handles more tubes per minute.

How It Works:

- Advanced servo motors increase speed.

- Automated sensors detect tube positions.

- New filling nozzles reduce spillage.

An Automatic Filling Machine optimizes production lines.

2. Smart Automation and AI Integration

A Tube Filling and Sealing Machine now includes AI technology. Smart systems improve accuracy.

AI Benefits:

- Detects errors before they cause defects.

- Adjusts filling volume automatically.

- Optimizes production speed in real-time.

An Automatic Filling Machine reduces manual adjustments.

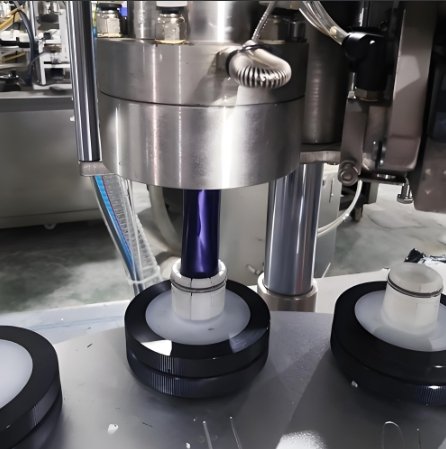

3. Improved Sealing Technology

A Tube Filling and Sealing Machine needs strong, airtight seals. New methods ensure better sealing.

Latest Sealing Methods:

- Ultrasonic Sealing: Uses sound waves for precision.

- Hot Air Sealing: Creates a secure, even seal.

- Laser Sealing: Ensures a tamper-proof finish.

An Automatic Filling Machine guarantees long-lasting seals.

4. Eco-Friendly and Sustainable Designs

A Tube Filling and Sealing Machine now supports eco-friendly packaging. Sustainability is a priority.

Green Innovations:

- Machines use biodegradable tubes.

- Energy-efficient motors reduce power usage.

- Automated waste management lowers material loss.

An Automatic Filling Machine helps businesses meet sustainability goals.

5. Multi-Product Compatibility

A Tube Filling and Sealing Machine must handle different products. New technology allows for versatility.

Product Types:

- Creams and gels.

- Lotions and pastes.

- Liquid and semi-solid products.

An Automatic Filling Machine adjusts settings for various viscosities.

6. Compact and Modular Machine Designs

A Tube Filling and Sealing Machine now features a smaller, modular design. It saves space and adapts easily.

Modular Benefits:

- Easy expansion with extra units.

- Quick setup for new products.

- Compact footprint for small factories.

An Automatic Filling Machine fits various production layouts.

7. Touchscreen Control Panels

A Tube Filling and Sealing Machine is now easier to use. Touchscreen controls improve efficiency.

New Control Features:

- Digital recipe storage for different products.

- One-touch calibration for fast setup.

- Remote monitoring for real-time adjustments.

An Automatic Filling Machine simplifies production management.

8. Enhanced Safety Features

A Tube Filling and Sealing Machine must meet strict safety standards. New features protect workers and products.

Safety Upgrades:

- Auto-stop function for tube misalignment.

- Enclosed filling areas to prevent contamination.

- Pressure sensors to prevent overfilling.

An Automatic Filling Machine ensures a safe work environment.

9. Integration with Smart Factory Systems

A Tube Filling and Sealing Machine now connects with factory networks. It improves efficiency and tracking.

Smart Factory Benefits:

- Monitors production in real-time.

- Sends automatic maintenance alerts.

- Reduces downtime with predictive analytics.

An Automatic Filling Machine streamlines factory operations.

10. Customizable Filling Solutions

A Tube Filling and Sealing Machine adapts to specific needs. New technology allows for full customization.

Customization Options:

- Adjustable fill volumes.

- Changeable sealing methods.

- Custom tube sizes and materials.

An Automatic Filling Machine meets unique production demands.

A Tube Filling and Sealing Machine has evolved for 2025. It is faster, smarter, and more efficient. An Automatic Filling Machine now includes AI, eco-friendly features, and smart controls.

Investing in the latest technology improves production quality. Businesses benefit from higher efficiency and lower costs. The future of tube filling is here.