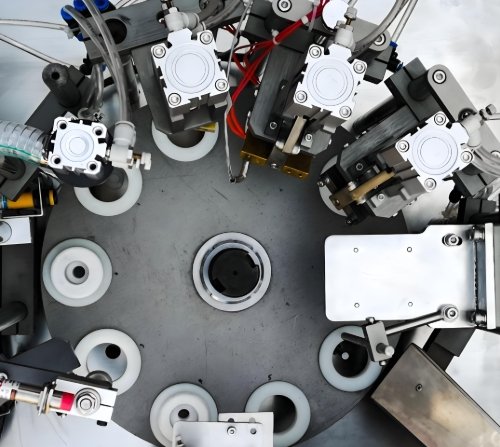

Modern businesses face growing challenges. They must balance speed, accuracy, and cost. The solution is automation. A Tube Filling and Sealing Machine and an Automatic Filling Machine are game-changers. These machines simplify production. They enhance quality and reduce waste. Here’s why businesses trust them.

1. Faster Production

Speed is essential in competitive industries. A Tube Filling and Sealing Machine operates much faster than manual processes. It fills and seals tubes in seconds. High-speed models handle thousands of units daily. Paired with an Automatic Filling Machine, production accelerates even more.

2. Enhanced Accuracy

Manual filling often causes mistakes. Overfilled or underfilled tubes waste materials. Automated machines ensure precision. They dispense exact amounts every time. This consistency improves product quality.

3. Cost Efficiency

Automation reduces labor costs. Fewer workers are needed to monitor machines. Additionally, precision minimizes material waste. Long-term savings make these machines a smart investment.

4. Versatility

A Tube Filling and Sealing Machine works with various products. Businesses in cosmetics, food, and pharmaceuticals use it. Machines handle creams, gels, pastes, and more. An Automatic Filling Machine adjusts easily for different product types.

5. Improved Hygiene

Hygiene is crucial in food and cosmetics industries. Automated machines maintain cleanliness. Many models feature self-cleaning systems. They meet strict safety standards.

6. Reduced Human Error

Human errors slow production. Automation eliminates this risk. Machines perform repetitive tasks without fatigue. This ensures smooth operations.

7. Scalability

As businesses grow, so do their production needs. An Automatic Filling Machine adapts to higher demands. It handles increased volumes without compromising quality.

Advanced Features of Modern Machines

1. Digital Interfaces

Operators control settings easily. Touchscreens simplify adjustments.

2. Smart Sensors

Sensors detect issues instantly. They reduce downtime.

3. Multi-Tube Compatibility

Machines adjust for various tube sizes.

4. Leak Detection

Systems identify and fix leaks quickly.

Industries Benefiting from Automation

Cosmetics

Fills lotions, creams, and gels precisely.

Food

Handles sauces, spreads, and condiments.

Pharmaceuticals

Manages ointments and medicinal gels with care.

Industrial Products

Fills adhesives, lubricants, and sealants.

How an Automatic Filling Machine Supports Growth

An Automatic Filling Machine complements the tube sealing process. It integrates seamlessly with production lines. Automation ensures consistent quality. It also saves time and resources. Businesses achieve higher outputs effortlessly.

Common Issues Solved by Automation

1. Slow Production

Machines work faster than manual labor.

2. Inconsistent Filling

Automation ensures uniformity.

3. Material Waste

Precise dispensing minimizes loss.

4. High Labor Costs

Fewer workers are needed for operations.

Maintenance Tips for Long-Term Performance

1. Regular Cleaning

Remove residue to prevent clogs.

2. Inspect Sensors

Check for proper functioning.

3. Update Software

Ensure systems run efficiently.

4. Replace Worn Parts

Address wear and tear promptly.

Future of Tube Filling and Sealing

Automation is evolving. Machines will become smarter. Artificial intelligence will improve efficiency. IoT systems will enable remote monitoring. These advancements will make Tube Filling and Sealing Machines even more indispensable.

Modern businesses need efficiency. A Tube Filling and Sealing Machine delivers this. Paired with an Automatic Filling Machine, it transforms production. These machines offer speed, accuracy, and cost savings.

Choosing automation is essential for staying competitive. Invest in these machines today. They ensure long-term success in any industry.