Filling machines are essential in the production of household products. From detergents to cleaners, filling machines ensure fast, accurate, and efficient packaging. Household products come in different forms, including liquids, gels, and powders. Each requires a specific type of filling machine to handle its unique properties. With the demand for household products growing, automatic filling machines play a crucial role in meeting production goals.

1. Why Filling Machines Matter in Household Products

Household products need to be packaged quickly and consistently. Manual filling can’t keep up with the demand. This is why filling machines are vital. They automate the process, making production faster and more accurate. These machines reduce human error, ensuring each container is filled with the right amount.

Automatic filling machines further enhance this process. They offer speed, precision, and the ability to handle large production volumes. They are programmed to work continuously without the need for constant supervision.

2. Types of Filling Machines for Household Products

Different household products require different types of filling machines. The choice depends on the product’s viscosity, packaging type, and production speed. Here are some common types:

a. Liquid Filling Machines

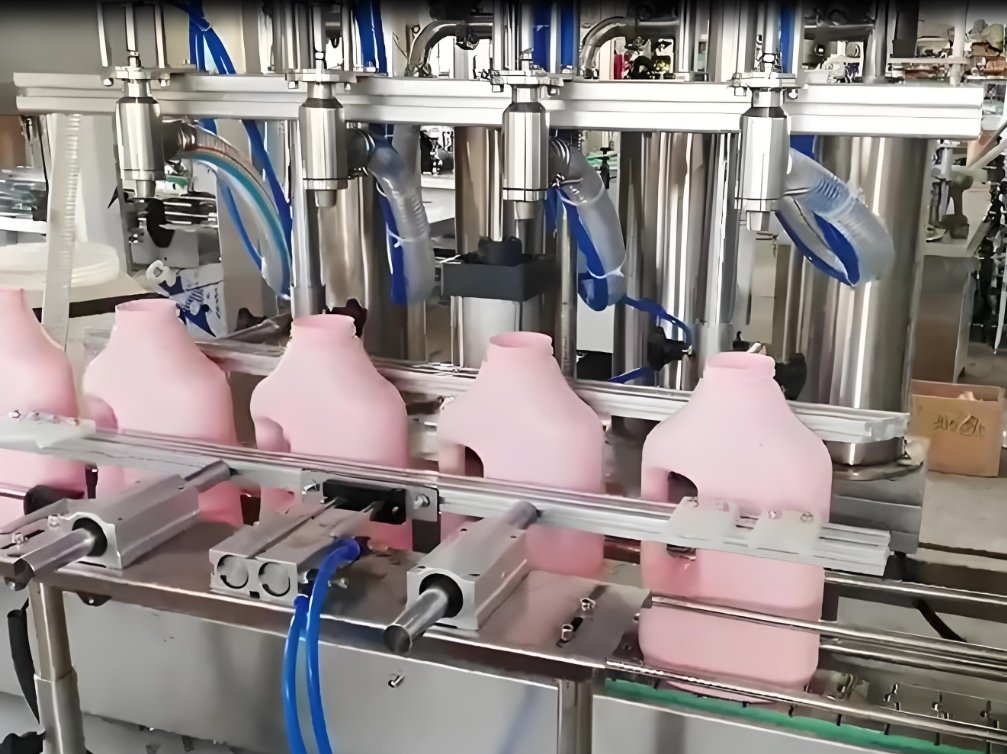

Liquid household products, like window cleaners and floor cleaners, need specialized filling machines. These machines are designed to handle liquids of varying viscosity. Automatic filling machines can fill thousands of bottles per hour, ensuring the process is quick and efficient.

b. Viscous Filling Machines

Thicker products like laundry detergents and fabric softeners need viscous filling machines. These machines are equipped with pumps that handle thick substances. Automatic filling machines for viscous products ensure precise filling without overflows or mess.

c. Powder Filling Machines

For products like powdered laundry detergents, specialized filling machines are required. These machines can handle dry products, ensuring they are measured and packed properly. Automatic filling machines can also weigh and fill powder products simultaneously, speeding up the process.

3. Benefits of Using Filling Machines for Household Products

Using filling machines in the household product industry brings many benefits. They streamline the production process and improve efficiency. Here are some key advantages:

a. Increased Production Speed

Automatic filling machines increase the speed of production. They can fill hundreds or even thousands of bottles in a short time. This allows manufacturers to meet high demand without delays.

b. Consistency

Filling machines ensure each container is filled with the exact same amount of product. This consistency is crucial for customer satisfaction. Automatic filling machines offer even more precision, reducing the risk of overfilling or underfilling.

c. Improved Hygiene

Household products must meet strict hygiene standards. Filling machines reduce the risk of contamination by minimizing human contact with the product. Automatic filling machines are designed with stainless steel parts, making them easy to clean and sanitize.

d. Reduced Waste

With manual filling, there is often product waste due to spills or inaccurate measurements. Filling machines prevent waste by delivering the exact amount needed. Automatic filling machines are even more precise, reducing product loss during packaging.

4. Challenges with Filling Machines in Household Products

While filling machines offer many benefits, they also come with challenges. It’s important to address these challenges to maximize their efficiency.

a. Maintenance

Automatic filling machines require regular maintenance to keep them in good working condition. Without proper maintenance, they may break down, causing production delays. Regular cleaning, part replacement, and lubrication are necessary to ensure smooth operation.

b. Cost

The initial investment in automatic filling machines can be high. This might be a challenge for smaller companies. However, the long-term benefits, including increased production speed and reduced waste, usually outweigh the upfront cost.

c. Training

Operating filling machines requires proper training. Employees need to know how to use the machines safely and effectively. With automatic filling machines, operators must understand how to program and troubleshoot the machines to prevent errors.

5. Choosing the Right Filling Machine for Household Products

Selecting the right filling machine is crucial for efficient production. Here’s how to choose the best one for your needs:

a. Product Type

The first thing to consider is the type of household product. Liquid products need different filling machines compared to powders or gels. Make sure the machine you choose is designed for the specific product you are packaging.

b. Production Volume

The size of your production run is another key factor. For large-scale production, an automatic filling machine is essential. These machines can handle high volumes efficiently. Smaller companies may opt for semi-automatic machines.

c. Packaging Type

Consider the type of packaging you are using. Different filling machines are suited for different types of containers, such as bottles, cans, or pouches. Make sure the machine can handle the packaging material and size you are using.

d. Budget

While automatic filling machines are more expensive, they offer long-term savings. These machines are a good investment for companies looking to scale up production. If your budget is tight, start with a semi-automatic machine and upgrade as your business grows.

6. Automation in Household Product Manufacturing

Automation is transforming the household product industry. Automatic filling machines are leading this change. They offer high-speed production with minimal human intervention. These machines can operate 24/7, allowing companies to meet tight deadlines.

Automation also improves accuracy. Automatic filling machines are equipped with sensors and programming that ensure the exact amount of product is filled every time. This reduces waste and ensures consistency across all products.

7. Future Trends in Filling Machines for Household Products

As technology advances, filling machines are becoming even more sophisticated. The future of filling machines will include smart features like artificial intelligence (AI) and the Internet of Things (IoT). These features will allow machines to self-diagnose and optimize their performance in real-time.

Sustainability is another trend shaping the future of filling machines. Companies are looking for eco-friendly packaging options. Filling machines will need to adapt to handle recyclable and biodegradable materials.

Filling machines play a critical role in the production of household products. They offer speed, accuracy, and efficiency, making them essential for large-scale production. Automatic filling machines take automation to the next level, ensuring that production lines run smoothly and without interruption.

While challenges like maintenance and cost exist, the benefits of using filling machines far outweigh these difficulties. Investing in the right automatic filling machine can improve production efficiency, reduce waste, and help companies meet the growing demand for household products.

As technology advances, filling machines will continue to evolve, offering even more opportunities for innovation in the household product industry.